Introduction

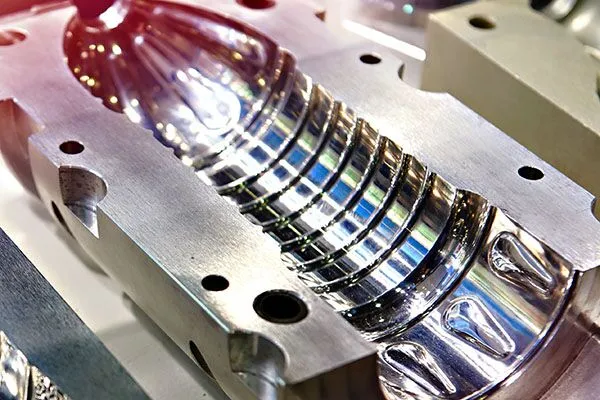

In the world of manufacturing, the quality of molded products depends not only on the materials and the design but also significantly on the mold surface treatment. Mold surface treatment refers to the process of modifying the surface of a mold to enhance its properties, such as texture, finish, and wear resistance. This is a crucial step in achieving superior product quality, extended mold life, and reduced production costs.

In this article, we will explore the significance of mold surface treatments, the various methods available, and how these treatments contribute to better product quality in different manufacturing sectors.

What is Mold Surface Treatment?

Mold surface treatment involves the application of various processes to alter the surface characteristics of the mold. These treatments are designed to achieve specific improvements in the mold’s performance, which in turn influences the quality of the products produced. The primary objectives of mold surface treatment are:

- Improved wear resistance

- Enhanced surface finish

- Better texture and aesthetic appeal

- Reduced friction

- Increased mold durability

By applying these treatments, manufacturers can prevent issues such as wear, corrosion, and oxidation, which can negatively affect the molding process and the quality of the final product.

How Mold Surface Treatment Enhances Product Quality

1. Improved Texture and Finish

The surface finish of a mold plays a significant role in determining the texture and appearance of the final molded product. A smooth, well-treated mold surface ensures that the molded part has a uniform, flawless finish. Whether it’s a glossy plastic part, a matte metal component, or a textured surface, mold surface treatment is essential for achieving the desired visual characteristics.

How it helps:

- Glossy finishes: For products like plastic enclosures or cosmetic items, a smooth, polished mold surface ensures a glossy, high-quality appearance.

- Matte finishes: For products requiring a more subdued look, surface treatments can ensure that the texture remains consistent.

- Custom textures: Surface treatments can be used to create intricate patterns or textures that add value to the product design.

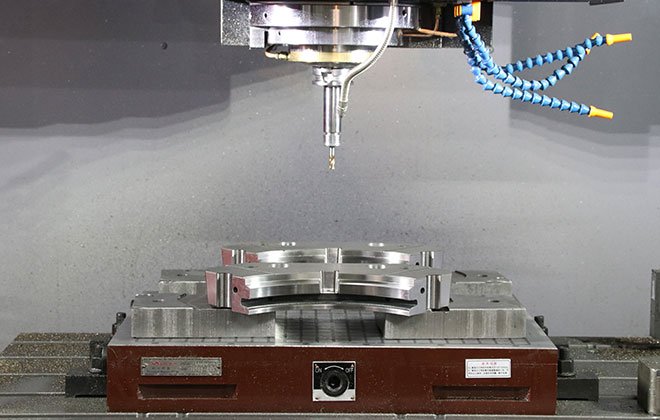

2. Enhanced Wear Resistance

During the molding process, molds are subjected to high temperatures, pressure, and repetitive mechanical stress. Without proper treatment, mold surfaces can degrade over time, leading to defects such as scratches, indentations, or material build-up. Surface treatments improve the mold’s resistance to wear and tear, ensuring consistent product quality across extended production runs.

How it helps:

- Increased lifespan: Molds that are more resistant to wear last longer, reducing the need for replacements and repairs.

- Consistent part quality: With fewer defects caused by mold wear, the final product maintains its quality throughout the production cycle.

3. Reduced Friction and Improved Flow

Friction between the molded material and the mold surface can cause several issues, including poor material flow, inconsistent part shapes, and longer cycle times. Surface treatments such as lubrication, polishing, or coating reduce friction, ensuring smoother material flow and faster cycle times, ultimately improving product consistency.

How it helps:

- Faster cycle times: With reduced friction, the molding process becomes more efficient, allowing manufacturers to produce more parts in less time.

- Smoother material flow: Materials like plastics or metals flow more evenly into the mold, preventing air pockets, bubbles, or inconsistencies in the molded part.

4. Corrosion Resistance

Molds are often exposed to corrosive substances or moisture during production, especially when working with metals or certain plastic compounds. Surface treatments like coatings or plating can protect the mold from corrosion, extending its service life and maintaining the integrity of the final product.

How it helps:

- Protects mold surfaces: Coatings like nickel plating or chromium coatings provide a protective barrier against corrosion, preventing mold deterioration.

- Improved product quality: Corrosion can lead to surface defects and uneven texture on the molded parts. Preventing corrosion helps maintain high-quality finishes.

5. Increased Mold Durability

Mold surface treatment increases the overall durability of molds by strengthening the mold’s surface against harsh production conditions. This not only improves the mold’s performance but also prevents premature mold failure, leading to fewer production delays and less downtime.

How it helps:

- Longer mold life: Stronger mold surfaces resist damage caused by wear, heat, and pressure, ensuring that the molds can withstand prolonged use.

- Fewer mold replacements: Durability translates into fewer replacements or repairs, leading to cost savings and higher production efficiency.

Methods of Mold Surface Treatment

Several surface treatment methods can be used depending on the material of the mold, the desired characteristics of the final product, and the production environment. Some of the most common mold surface treatments include:

1. Electroplating

Electroplating involves the application of a thin layer of metal (such as nickel, chrome, or gold) to the mold surface using electrical current. This treatment improves the mold’s wear resistance and corrosion resistance, making it ideal for metal molds.

2. Plasma Treatment

Plasma treatment uses an ionized gas to modify the mold surface. This technique improves adhesion and cleanliness and is often used in the production of plastic molds to improve the surface finish and prevent material buildup.

3. Nitride Hardening

In nitride hardening, nitrogen is introduced to the mold surface at high temperatures, making the surface harder and more wear-resistant. This is a common treatment for molds used in high-stress environments, such as automotive or aerospace parts.

4. Coatings

Applying coatings such as PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) can provide a durable surface finish that enhances both wear resistance and aesthetic appeal. These coatings are commonly used on molds for plastic injection molding or die-casting.

5. Polishing

Polishing smooths out the mold surface to a high-gloss finish, reducing friction and improving material flow. This method is often used for cosmetic products or high-end plastics, where a flawless finish is essential.

Benefits of Mold Surface Treatment

✅ 1. Improved Aesthetics

A mold that has undergone surface treatment will produce products with superior visual appeal, free from imperfections or unsightly marks. This is especially important in industries where the appearance of the product plays a critical role, such as cosmetics and consumer electronics.

✅ 2. Enhanced Production Efficiency

Surface-treated molds can improve the overall efficiency of production by reducing cycle times and maintenance costs. With lower friction and better flow, the molding process becomes faster and more consistent, reducing delays and downtime.

✅ 3. Cost-Effective in the Long Run

Although mold surface treatments may involve upfront costs, they pay off in the long run. By extending mold life, improving product quality, and reducing defects, manufacturers can achieve greater cost-effectiveness and sustainability.

Applications of Mold Surface Treatment

🚗 Automotive Industry

In automotive manufacturing, mold surface treatments are essential for producing durable, high-quality parts like bumpers, dashboard components, and grills, where precision and surface integrity are key.

🖥️ Electronics Industry

In the electronics sector, plastic enclosures for electronic devices such as smartphones and computers require a high-quality surface finish. Mold surface treatment ensures that these components have a smooth, durable finish, free from imperfections.

🍽️ Consumer Goods Industry

For household products, such as containers, appliances, and kitchen tools, mold surface treatment ensures smooth finishes, better material flow, and reduced wear, which helps in maintaining quality over longer production runs.

Conclusion

Mold surface treatment plays a critical role in improving the quality, durability, and efficiency of the molding process. By enhancing the texture, finish, and wear resistance of molds, manufacturers can produce high-quality products with fewer defects and reduced production costs. As industries continue to demand higher-quality standards and more efficient production, mold surface treatment will remain an essential practice in achieving these goals.

Frequently Asked Questions (FAQs)

Q1: What is the purpose of mold surface treatment?

A: Mold surface treatment improves the mold’s texture, finish, wear resistance, and durability, ensuring the production of high-quality products with fewer defects.

Q2: How does mold surface treatment affect product quality?

A: Surface treatment enhances the aesthetic finish, reduces defects, and improves the overall durability of the product, leading to higher quality and longer-lasting molded parts.

Q3: Are all molds treated with surface treatments?

A: While not all molds require surface treatments, those that are used in high-stress, high-volume production or for products that require high precision will benefit significantly from surface treatment.

Q4: How often should molds be treated or maintained?

A: The frequency of mold surface treatment depends on the type of mold, the material being molded, and the intensity of the production process. Regular maintenance and periodic treatments are recommended to extend the mold’s lifespan.

Sources

- MoldMaking Technology – The Rise of Smart Molds

- Plastics Technology – How Smart Mold Systems Enhance Efficiency

- Automation World – The Role of IoT in Mold Management

- Industry Today – Predictive Maintenance in Mold Production

- Advanced Manufacturing – Smart Mold Applications in the Automotive Industry