Introduction

In the world of industrial manufacturing, achieving high-quality, precise, and durable parts is essential to the success of any production process. Diecast aluminum injection molds have become an integral tool in modern manufacturing, especially in industries that require mass production with exact specifications. These molds offer unique advantages, such as strength, precision, and the ability to handle high-volume production, making them a preferred choice in various applications, from automotive parts to electronics. In this article, we will explore the power of diecast aluminum injection molds and how they contribute to enhanced manufacturing processes and product quality.

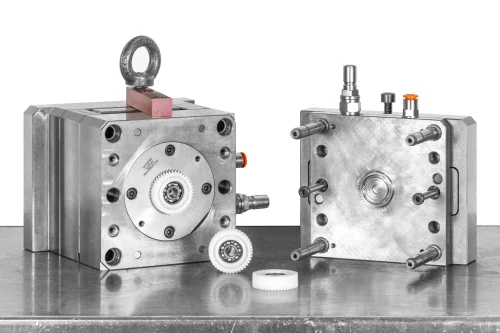

What Are Diecast Aluminum Injection Molds?

Diecast aluminum injection molds are molds used to shape molten aluminum into specific forms, using high-pressure injection to force the molten metal into a mold cavity. The process of die-casting with aluminum offers several benefits, including speed, efficiency, and the ability to create highly detailed components. Diecast aluminum molds are specifically designed to provide high levels of precision and can be used in various industries for manufacturing lightweight yet durable products.

- Fact: Aluminum die casting accounts for approximately 80% of non-ferrous die-cast products used in industries like automotive, electronics, and aerospace.

Diecast aluminum molds are known for their ability to produce large quantities of parts at consistent quality levels, making them highly suitable for high-volume production processes. They also offer the benefit of a smooth, high-quality finish that minimizes the need for additional finishing or machining steps.

Key Advantages of Diecast Aluminum Injection Molds

Diecast aluminum injection molds are widely regarded for their ability to meet the demanding needs of industries that require both precision and durability. Let’s break down the key advantages that make diecast aluminum injection molds an essential tool in industrial applications:

1. Durability and Strength

Aluminum is a strong and lightweight metal that exhibits impressive durability under high-pressure conditions. Diecast aluminum injection molds can withstand the extreme pressure and temperature conditions involved in the injection molding process without deforming or wearing out quickly. This makes them ideal for producing parts that need to endure harsh operating conditions.

- Statistic: Aluminum alloys used in die-casting processes are known for their tensile strength, with some alloys reaching up to 310 MPa, making them suitable for applications requiring high strength-to-weight ratios.

2. Precision and Accuracy

The precision of diecast aluminum injection molds is another key advantage. The high-pressure molding process ensures that each part produced is highly accurate and adheres to tight tolerances. This is crucial for industries such as automotive manufacturing, where even the smallest deviation in a part’s dimensions can have significant consequences for assembly and performance.

- Example: In the automotive industry, diecast aluminum injection molds are used to create engine blocks, transmission housings, and other critical components where precision is paramount.

3. High-Volume Production Capability

One of the standout features of diecast aluminum injection molds is their ability to handle high-volume production efficiently. The high-pressure molding process can produce hundreds or even thousands of parts in a relatively short amount of time. This capability makes diecast aluminum molds highly suitable for industries where mass production is required, such as automotive, electronics, and consumer goods manufacturing.

- Fact: Diecasting with aluminum allows for production rates of over 200 parts per hour, depending on the size and complexity of the components.

4. Cost Efficiency for Mass Production

While the initial cost of creating diecast aluminum molds can be high, the long-term benefits are significant in terms of cost efficiency. The high-volume production capability allows manufacturers to produce large quantities of parts at a relatively low per-unit cost. Once the mold is created, the production process becomes highly automated and efficient, reducing the cost per part significantly.

- Statistic: The cost per unit for aluminum diecast parts can be reduced by as much as 30-40% when high-volume production is reached.

5. Complex Designs and Thin-Walled Parts

Diecast aluminum injection molds allow for the production of parts with complex geometries and thin walls, which is often a challenge with other manufacturing methods. The precision of the die-casting process enables manufacturers to create parts with intricate designs, fine details, and precise wall thicknesses. This capability is particularly valuable in industries where parts need to be lightweight yet strong, such as aerospace and electronics.

- Example: In the electronics industry, diecast aluminum molds are often used to create enclosures for electronic devices, where thin walls are required to reduce weight without compromising on strength.

Applications of Diecast Aluminum Injection Molds

Diecast aluminum injection molds have broad applications across multiple industries due to their versatility, strength, and ability to produce parts with high precision. Let’s explore some of the industries that benefit most from this technology.

Automotive Industry

The automotive industry is one of the largest users of diecast aluminum molds. Aluminum die-casting provides a lightweight yet durable solution for manufacturing critical automotive parts such as engine blocks, transmission components, and structural elements. The high-precision molding process ensures that these parts meet stringent quality standards and performance requirements.

- Statistic: Aluminum die-casting accounts for more than 70% of the castings used in modern vehicles, contributing to weight reduction and improved fuel efficiency.

Electronics Industry

Diecast aluminum molds are also commonly used in the electronics industry to create durable and lightweight enclosures for electronic devices. The high-precision and fine detail achievable with aluminum diecasting are essential in manufacturing parts that house sensitive electronic components while maintaining aesthetic appeal.

- Example: Smartphone manufacturers often use diecast aluminum injection molds to produce the casings for their devices, ensuring a sleek design with excellent strength-to-weight ratios.

Aerospace Industry

In the aerospace industry, diecast aluminum injection molds are used to produce components that need to meet strict standards for both strength and weight. Diecast aluminum parts are ideal for aerospace applications because they offer an excellent balance of durability and low weight, which is crucial in reducing overall aircraft weight while maintaining structural integrity.

- Fact: The aerospace sector relies on aluminum diecasting for critical parts such as airframe components, engine brackets, and landing gear parts.

Consumer Goods and Industrial Equipment

Beyond automotive, electronics, and aerospace, diecast aluminum injection molds are used to produce components for consumer goods and industrial equipment. From household appliances to heavy machinery, aluminum diecasting is an effective method for producing high-quality, durable parts.

- Example: Industrial manufacturers use aluminum die-cast molds for producing parts like pump housings, compressors, and valve components.

Challenges and Solutions in Diecast Aluminum Injection Molding

While diecast aluminum injection molds offer many advantages, they are not without their challenges. Below are some common challenges faced by manufacturers when using aluminum diecast molds, along with solutions to overcome them:

1. High Initial Mold Cost

The initial cost of producing diecast aluminum molds can be relatively high, especially for complex parts. However, the high-volume production benefits often outweigh the upfront costs. Manufacturers can offset the initial cost by increasing production runs to achieve lower per-unit costs.

- Solution: Focus on high-volume production to maximize the cost-efficiency of the diecast aluminum molds.

2. Porosity in Cast Parts

Porosity, or the formation of small air pockets within the cast part, can be a problem in aluminum die-casting. This issue can affect the structural integrity and aesthetic quality of the parts.

- Solution: Manufacturers can improve the quality of castings by optimizing the injection process, using advanced alloy compositions, and ensuring proper venting in the mold.

3. Complex Design Limitations

While diecast aluminum molds can handle complex designs, there are still limitations in terms of the wall thickness and undercut features. Overcoming these limitations requires careful mold design and planning.

- Solution: Employ advanced mold design techniques and utilize technologies such as simulation software to predict potential issues before production.

Conclusion

Diecast aluminum injection molds have proven themselves to be a powerful tool in industrial manufacturing, offering unmatched durability, precision, and the ability to handle high-volume production. These molds are essential for producing complex, high-quality components in industries like automotive, electronics, aerospace, and consumer goods. By understanding the benefits and challenges of diecast aluminum injection molds, manufacturers can make informed decisions that optimize production efficiency and product quality.

Frequently Asked Questions (FAQ)

1. What are the main advantages of diecast aluminum injection molds?

Diecast aluminum injection molds offer durability, precision, high-volume production capacity, and the ability to create complex and lightweight parts. They are ideal for industries that require mass production of parts with exact specifications.

2. How do diecast aluminum molds compare to other types of molds?

Compared to other types of molds, diecast aluminum molds offer superior strength, precision, and the ability to handle high-pressure molding. They are also more cost-effective for large production runs, though they may require a higher initial investment.

3. What industries benefit most from diecast aluminum molds?

Industries like automotive, aerospace, electronics, and consumer goods rely heavily on diecast aluminum molds due to their ability to produce lightweight, durable, and highly detailed parts.

4. Are diecast aluminum molds suitable for small production runs?

While diecast aluminum molds are more cost-effective for large production runs, they can still be used for small production runs if the parts require high precision and durability. However, the initial mold cost might be higher for smaller batches.

5. How long do diecast aluminum molds last?

The lifespan of a diecast aluminum mold depends on the material used, the complexity of the design, and the frequency of use. Generally, these molds can last for tens of thousands of cycles before requiring replacement or maintenance.

Sources:

- Aluminum Die Casting for the Automotive Industry – Manufacturing Insights, 2021

- Aerospace Aluminum Casting Applications – Aerospace Industry Reports, 2020

- Die Casting Process Efficiency – Industrial Molding Magazine, 2022