Introduction

In the world of mold manufacturing, efficient Optimize mold cooling systems are essential for reducing cycle times and ensuring consistent product quality. Mold cooling systems play a critical role in controlling the temperature of molds during the manufacturing process, especially for thermoplastic materials that require precise cooling rates. An optimized cooling system can significantly reduce production times, increase throughput, and improve the consistency of the finished product. In this article, we will explore 5 effective ways to optimize mold cooling systems for better performance and cost efficiency.

1. Properly Design the Cooling Channels

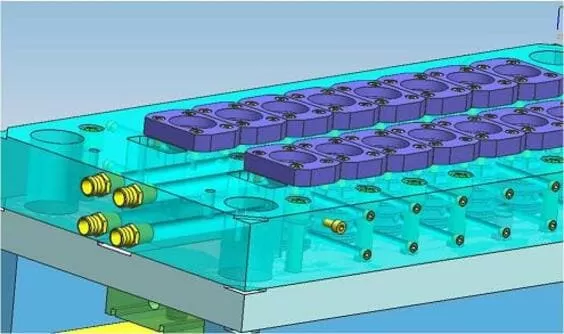

The design of cooling channels within a mold is one of the most crucial factors in optimizing the cooling system. The layout, size, and placement of cooling channels directly affect the cooling efficiency. For optimal cooling, the channels should be placed as close to the molded part as possible and in uniform distribution to ensure even Optimize mold cooling systems across the entire mold.

How to optimize:

- Use conformal cooling channels: to Optimize mold cooling systems These are 3D-printed cooling channels that conform to the shape of the mold cavity, offering superior cooling and reducing cycle times.

- Ensure uniform cooling: to Optimize mold cooling systems Channels should be designed to ensure that the temperature difference between different areas of the mold is minimal.

- Use advanced simulation tools: to Optimize mold cooling systems CAD and simulation tools can help in designing the most efficient cooling channel layout before mold fabrication.

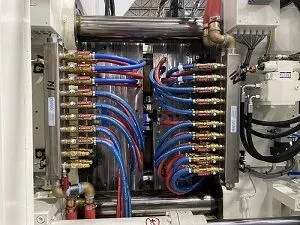

2. Maintain Optimal Flow of Cooling Water

Ensuring that the cooling water flows effectively and consistently through the cooling channels is essential for optimizing the cooling system. Water temperature and pressure are key factors that determine the rate of heat transfer from the mold to the Optimize mold cooling systems fluid.

How to optimize:

- Maintain consistent water temperature: to Optimize mold cooling systems Cooling water should be kept at an optimal temperature to ensure it absorbs heat efficiently from the mold. Too hot or too cold water can lead to thermal shock and affect part quality.

- Monitor water flow rate: An optimal flow rate ensures that the cooling water moves efficiently through the channels, maintaining a steady cooling effect. Too high or too low of a flow rate can lead to uneven cooling.

- Use a temperature control unit (TCU): A TCU regulates the temperature of the cooling water, ensuring consistent flow and optimal cooling throughout the cycle.

3. Use the Right Cooling Media

While water is the most commonly used Optimize mold cooling systems media, it is not always the best choice for all molding processes. The selection of cooling media can have a significant impact on the efficiency of the cooling system, depending on the material being molded and the specific requirements of the production process.

How to optimize:

- Use water-soluble cooling fluids: For certain applications, water-soluble fluids or specially designed cooling agents can provide better heat transfer properties and reduce the risk of corrosion.

- Consider other fluids for specialized processes: For materials that require extremely precise cooling or have higher thermal conductivity, using oil-based coolants or ethylene glycol solutions can be more effective.

- Use additives to improve cooling performance: Additives like corrosion inhibitors or anti-foam agents can improve the longevity of cooling fluids and maintain efficient heat transfer over time.

4. Optimize Mold Temperature Control

Maintaining a consistent mold temperature is vital for controlling the cooling rate and ensuring the desired part quality. Proper temperature control prevents issues such as warping, internal stresses, and part defects caused by uneven cooling.

How to optimize:

- Use multiple temperature control zones: For large molds, multiple temperature control zones can be installed to ensure consistent temperatures across all areas of the mold.

- Adjust temperature based on material: Different materials require different cooling rates. For example, thermoplastics may need faster cooling rates compared to thermoset plastics, and mold temperatures should be adjusted accordingly.

- Utilize mold temperature controllers (MTCs): These devices regulate the temperature within the mold, preventing temperature fluctuations and ensuring stable production.

5. Implement Regular Maintenance and Inspections

Mold cooling systems can lose their efficiency over time due to clogging, wear and tear, or corrosion of the cooling channels. Regular maintenance and inspections are crucial to ensure that cooling systems continue to perform optimally.

How to optimize:

- Clean cooling channels regularly: Regular cleaning prevents blockages in cooling channels caused by scale buildup or debris. This ensures a consistent flow of cooling media and effective heat transfer.

- Inspect for leaks: Ensure that all cooling system components, including hoses, valves, and seals, are leak-free to maintain pressure and flow rates.

- Replace damaged components: Cooling system components such as pumps, seals, and valves should be regularly inspected for wear and replaced when necessary to avoid system failures.

Benefits of Optimizing Mold Cooling Systems

✅ Reduced Cycle Times

Efficient cooling systems help reduce the time it takes for the molded part to cool and solidify, directly decreasing cycle times and increasing production efficiency.

✅ Improved Product Quality

Uniform and controlled cooling ensures consistent part quality, minimizing defects such as warping, sink marks, and internal stresses.

✅ Increased Mold Lifespan

By maintaining optimal cooling conditions, molds are less prone to overheating, which reduces wear and tear, extending their service life.

✅ Lower Energy Consumption

Optimized cooling systems use energy more efficiently, which can lead to reduced operational costs over time.

Conclusion

Optimizing mold cooling systems is a key factor in improving production efficiency, reducing cycle times, and ensuring consistent product quality. By focusing on the proper design of cooling channels, maintaining optimal flow and temperature control, selecting the right cooling media, and performing regular maintenance, manufacturers can significantly enhance the performance of their mold cooling systems. Implementing these strategies not only leads to better-quality products but also improves the overall cost-effectiveness and longevity of molds in production.

Frequently Asked Questions (FAQs)

Q1: How does the cooling channel design impact mold performance?

A: The layout and placement of cooling channels affect how evenly heat is transferred from the mold to the cooling fluid. Properly designed channels ensure uniform cooling, which improves product quality and reduces cycle times.

Q2: Can I use water for all types of molds?

A: Water is suitable for most molds, but for specific materials or processes, oil-based coolants or other specialized fluids may be required for better heat transfer or material compatibility.

Q3: How often should mold cooling systems be maintained?

A: Mold cooling systems should be inspected and cleaned regularly to ensure there are no blockages or leaks. The frequency of maintenance depends on the production volume and the type of cooling fluid used.

Q4: What are the consequences of poor mold cooling?

A: Poor mold cooling can lead to uneven part quality, including defects like warping, sink marks, and surface imperfections. It can also increase cycle times and decrease mold lifespan.

Sources

- Improve The Cooling Performance Of Your Molds

- Importance of cooling in the injection molding process

- Injection Mold Cooling System Design: A Complete Guide