Introduction

Molds play a critical role in the automotive industry, contributing to the production of a wide range of components that are essential for vehicle performance, safety, and aesthetics. From engine parts to interior elements, the use of molds enables manufacturers to create high-quality, precise, and cost-effective automotive components. In this article, we’ll explore the key uses of molds in the automotive industry, showcasing how they contribute to improved performance, design, and overall vehicle functionality.

1. Engine Components

Role of Molds:

Engine components, such as cylinder heads, engine blocks, and intake manifolds, are some of the most critical parts of a vehicle. These components require high precision to ensure optimal performance, fuel efficiency, and safety. molds in the automotive industry are used to cast these parts in metal or other materials, ensuring that each component meets the required specifications for strength, durability, and functionality.

How Molds Enhance Performance:

Molded engine components are engineered to withstand high levels of heat, pressure, and stress. The precision offered by molds ensures that engine parts fit perfectly, contributing to smoother operation and reduced wear over time. Furthermore, molds allow for complex designs, helping to optimize engine airflow and efficiency.

2. Exterior Body Parts

Role of Molds:

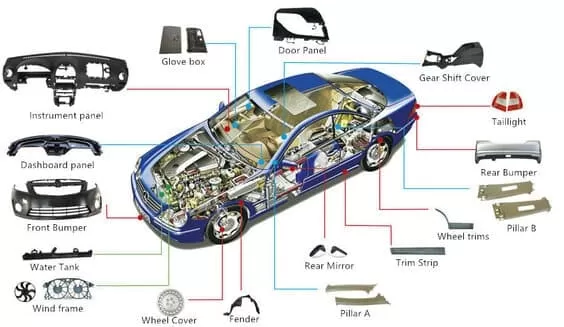

Exterior body parts, including bumpers, fenders, hoods, and doors, are commonly produced using molds. These components must not only be aesthetically pleasing but also durable enough to protect passengers and withstand environmental conditions. The use of molds in the automotive industry allows manufacturers to produce these parts in various materials, such as plastics, composites, and metals.

How Molds Enhance Design and Durability:

Molds enable manufacturers to achieve complex shapes and smooth finishes that are required for modern automotive designs. The ability to produce lightweight yet strong exterior parts enhances both the vehicle’s fuel efficiency and safety. Additionally, molded body parts are often designed to be more resistant to corrosion and wear, increasing the vehicle’s lifespan.

3. Interior Components

Role of Molds:

Molds are extensively used in the production of automotive interior components such as dashboards, door panels, seats, and trim pieces. These components require both aesthetic appeal and functional performance, often integrating various technologies and features, such as airbags and electronic controls.

How Molds Contribute to Aesthetics and Functionality:

Molded interior components are designed for both comfort and style. The flexibility of molds allows manufacturers to incorporate ergonomic features, intricate designs, and high-quality finishes. Molds also enable the integration of different materials, such as soft-touch plastics and fabrics, to improve the overall comfort and appeal of the vehicle’s interior.

4. Structural Components

Role of Molds:

In addition to the visible parts of a vehicle, molds in the automotive industry are used to create key structural components like chassis parts, suspension components, and brackets. These components are critical for the vehicle’s safety, handling, and overall performance.

How Molds Improve Strength and Precision:

Using molds in the automotive industry to produce structural components ensures that parts meet stringent quality and safety standards. The high precision of molded parts helps improve the vehicle’s overall stability and handling, while the ability to use advanced materials like aluminum or high-strength steel ensures that these components are both lightweight and durable.

5. Lighting and Electrical Components

Role of Molds:

Automotive lighting systems, including headlights, taillights, and indicator lights, are often produced using molds. These components need to be precise, durable, and resistant to extreme conditions such as high temperatures, vibrations, and moisture.

How Molds Enhance Functionality:

molds in the automotive industry help ensure that lighting components are produced with the required optical clarity, structural integrity, and precise fit. This enables better performance of the lighting systems, ensuring improved visibility, safety, and aesthetic appeal. Additionally, molded electrical components, like connectors and housings, ensure reliability and protection against electrical failure.

6. Airbags and Safety Components

Role of Molds:

molds in the automotive industry are also essential for producing safety components, such as airbags, seatbelt components, and crash sensors. These parts are crucial for ensuring passenger safety during accidents and require the highest level of precision and reliability.

How Molds Ensure Safety and Reliability:

The use of molds in the automotive industry allows manufacturers to produce safety components with exact specifications, ensuring that they function properly when needed. For example, airbags must deploy in a fraction of a second, so the precision of molded parts is essential for ensuring that these components perform optimally under extreme conditions.

7. Acoustic Components

Role of Molds:

molds in the automotive industryare used in the production of acoustic components like soundproofing materials, interior trim, and noise-reducing parts. These components play a crucial role in enhancing the driving experience by reducing noise and vibration levels inside the vehicle.

How Molds Improve Comfort:

By using molds in the automotive industry to create complex and precise soundproofing components, manufacturers can achieve better noise reduction and vibration control. This improves the overall comfort and quality of the driving experience, allowing for a quieter cabin environment and enhancing vehicle appeal.

Conclusion

molds in the automotive industry are an essential part of the automotive manufacturing process, enabling the production of high-performance, durable, and aesthetically appealing components. From engine parts to interior and safety components, molds contribute to the vehicle’s overall functionality, design, and safety. As the automotive industry continues to evolve, the use of molds will remain critical in meeting the demands for innovation, performance, and quality in vehicle production.

Frequently Asked Questions (FAQs)

Q1: What materials are commonly used in automotive molding?

A: Common materials used in automotive molding include metals (such as aluminum and steel), plastics (such as ABS, polypropylene, and polycarbonate), composites, and elastomers. These materials are selected based on the specific requirements for strength, weight, and durability.

Q2: How do molds contribute to vehicle safety?

A: Mmolds in the automotive industryare used to create critical safety components such as airbags, seatbelts, and crash sensors, ensuring that these parts meet strict safety standards. The precision of molded components ensures that they function correctly during accidents, helping protect passengers.

Q3: Can molds be used to create complex shapes in automotive parts?

A: Yes, molds enable the production of complex shapes and intricate designs, which are essential in modern automotive manufacturing. This includes body panels, interior components, and advanced parts with integrated technologies.

Q4: How does molding affect the performance of engine components?

A: Molding ensures that engine components like cylinder heads and engine blocks are produced with high precision, which is crucial for optimal engine performance. Molds help achieve the required strength, durability, and heat resistance for these critical parts.

Q5: What role do molds play in enhancing the aesthetic appeal of vehicles?

A: Molds are essential for producing exterior and interior parts with smooth finishes, precise dimensions, and custom designs. This helps manufacturers meet customer demands for attractive, modern, and high-quality vehicles.

Sources:

Automotive Manufacturing Solutions – “How Molding Shapes the Future of Car Parts.”

Plastics in Automotive – “The Role of Molding in Vehicle Production.”

Automotive Engineering – “The Evolution of Molds in the Automotive Industry.”

Suggested Topics