Introduction

In the world of consumer goods production, efficiency, quality, and innovation are paramount. From household products and packaging to personal care items, the demand for high-quality, cost-effective goods continues to rise. One of the most critical components driving this transformation is mold technology. Molds in Consumer Goods have revolutionized the consumer goods industry by enabling mass production of products with exceptional precision and consistency. This article explores how molds are reshaping the consumer goods sector and allowing manufacturers to meet the ever-growing demands of the market.

1. Enabling Mass Production with Consistency

Role of Molds:

The consumer goods industry thrives on high-volume production, and Molds in Consumer Goods are at the heart of this process. Molds allow manufacturers to produce large quantities of identical items quickly and consistently, which is crucial in meeting market demands efficiently.

How Molds Ensure Consistency:

Molds in Consumer Goods are designed to create identical products with minimal variation, ensuring that every item produced meets the same quality standards. This consistency is vital for products like packaging, household goods, and personal care items, where uniformity in appearance and function is critical. With molds, manufacturers can replicate designs accurately, whether producing thousands of items or millions, guaranteeing that consumers receive the same level of quality in every unit.

2. Enhancing Design Flexibility and Innovation

Role of Molds:

One of the biggest advantages of molds is the flexibility they provide in design. As consumer tastes evolve and trends change, manufacturers must be able to adapt quickly. Molds in Consumer Goods enable rapid prototyping and iterative design, allowing companies to innovate and bring new products to market faster.

How Molds Facilitate Innovation:

Molds in Consumer Goods technology allows manufacturers to experiment with different shapes, sizes, and material combinations. Whether it’s a new type of packaging, a more ergonomic household product, or a personalized personal care item, molds enable manufacturers to explore creative designs and bring them to life efficiently. The versatility of molds means that companies can easily adjust to market trends, offering innovative products that cater to the changing preferences of consumers.

3. Cost Efficiency and Material Optimization

Role of Molds:

Producing consumer goods at scale requires careful attention to cost management. Molds in Consumer Goods provide a cost-effective solution for high-volume manufacturing by reducing labor and material costs. In addition, molds help minimize waste by using the exact amount of material required to form each product.

How Molds Drive Cost Efficiency:

Once a mold is created, it can be used repeatedly to produce high quantities of products, reducing production time and labor costs. Additionally, molding technologies like injection molding optimize material use, ensuring that waste is minimized. By enabling the mass production of goods at a lower per-unit cost, molds contribute to significant savings for manufacturers and consumers alike.

4. Quality Control and Compliance

Role of Molds:

In industries like personal care and household goods, product quality is crucial for consumer satisfaction and safety. Molds in Consumer Goods play an important role in maintaining high quality and meeting regulatory standards. By ensuring that products are produced to exact specifications, molds help manufacturers comply with safety and quality regulations.

How Molds Ensure Quality:

Molds in Consumer Goods are designed to create products with tight tolerances, reducing the risk of defects or variations in size and shape. This precision helps ensure that each product performs as expected and meets safety standards. For example, in the production of food packaging or hygiene products, where safety is a top priority, molds are used to produce components that are both functional and compliant with regulatory standards such as FDA approval. The ability to consistently produce high-quality items is essential for building trust with consumers and avoiding costly recalls or legal issues.

5. Reducing Lead Time and Improving Time-to-Market

Role of Molds:

In today’s fast-paced market, the ability to bring products to market quickly is essential for staying ahead of competitors. Molds in Consumer Goods allow for rapid production of prototypes and finished goods, which reduces lead times and enables faster time-to-market for consumer goods.

How Molds Accelerate Production:

Molds in Consumer Goods allow manufacturers to create prototype parts quickly and accurately, enabling them to test designs before committing to full-scale production. Once the mold is perfected, it can be used to produce large quantities of products at high speed. This efficiency helps reduce the time it takes to get products into consumers’ hands, ensuring that companies can respond quickly to market demands and trends. By streamlining production, molds help brands launch new products faster and capitalize on emerging opportunities.

6. Sustainability and Environmental Benefits

Role of Molds in Consumer Goods:

As environmental concerns grow, there is increasing pressure on manufacturers to produce goods in a sustainable manner. Molds offer significant environmental benefits by enabling the efficient use of materials and reducing waste, making them a crucial component of green manufacturing practices.

How Molds in Consumer Goods Support Sustainability:

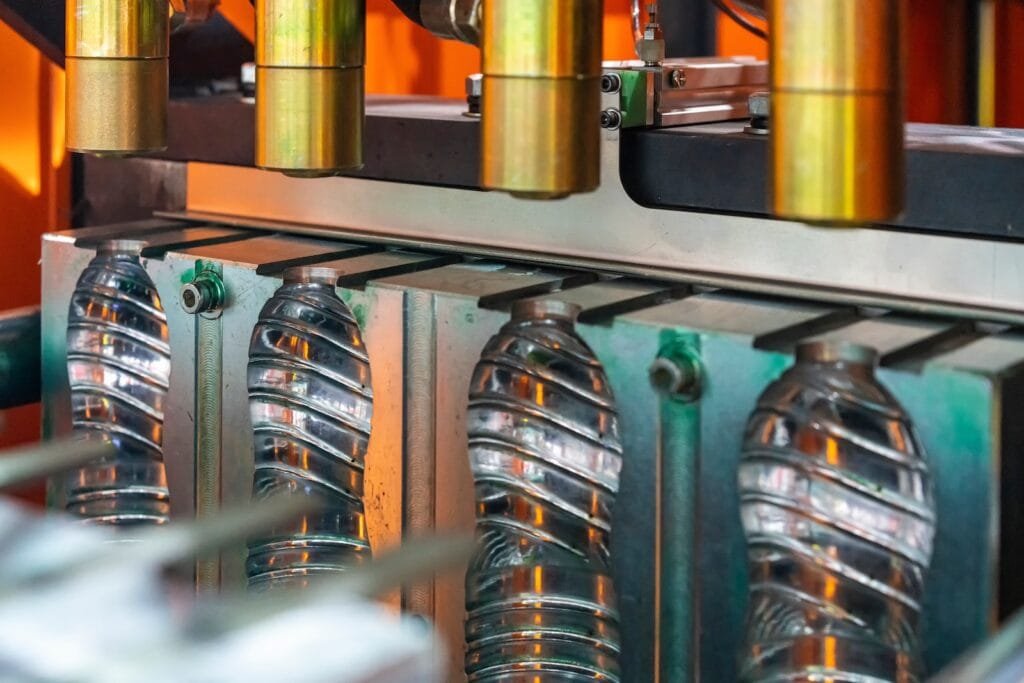

Molds help manufacturers optimize material usage, minimizing waste during production. In addition, molding technologies such as injection molding and blow molding can use recycled or biodegradable materials, further reducing the environmental impact of production. By improving the overall efficiency of the production process and reducing the need for raw materials, molds contribute to more sustainable manufacturing practices, which is increasingly important to environmentally-conscious consumers.

7. Customization for Consumer Preferences

Role of Molds:

The rise of personalized and customized products has opened new opportunities for consumer goods manufacturers. Molds in Consumer Goods allow for the efficient production of customized products, whether in terms of design, size, or material.

How Molds Enable Customization:

Mold technology can be adapted to create unique items that cater to individual customer preferences. This is particularly important in industries like fashion, home décor, and personal care, where consumers demand more personalized options. Whether it’s producing limited-edition packaging or custom-designed products, molds enable manufacturers to offer variations without compromising on quality or efficiency. This ability to produce customized goods at scale helps businesses stand out in a competitive market.

Conclusion

Molds have revolutionized the consumer goods production sector by offering efficient, cost-effective, and scalable solutions for high-quality manufacturing. They allow for the mass production of consistent, high-quality products while also enabling design flexibility, material optimization, and customization. As the demand for faster production, sustainable practices, and innovative designs grows, molds will continue to play a central role in shaping the future of the consumer goods industry.

Frequently Asked Questions (FAQs)

Q1: How do molds improve consistency in consumer goods production?

A: Molds provide precise control over the production process, ensuring that every product is identical in size, shape, and functionality, which is essential for quality assurance in the consumer goods sector.

Q2: What are the main advantages of using molds in mass production?

A: Molds enable high-speed, high-volume production with minimal material waste, leading to lower costs and faster turnaround times.

Q3: Can molds be used for producing customized consumer goods?

A: Yes, molds can be customized to produce unique designs and sizes, allowing manufacturers to cater to specific consumer preferences and trends.

Q4: How do molds support sustainability in consumer goods manufacturing?

A: Molds help minimize material waste, and modern molding techniques can use recycled or eco-friendly materials, contributing to more sustainable production practices.

Q5: What industries benefit most from mold technology in consumer goods production?

A: Industries such as packaging, personal care, household products, and fashion benefit greatly from mold technology due to its ability to produce high-quality, cost-effective products at scale.

Sources

- Aluminum Die Casting for the Automotive Industry – Manufacturing Insights, 2021

- Aerospace Aluminum Casting Applications – Aerospace Industry Reports, 2020

- Die Casting Process Efficiency – Industrial Molding Magazine, 2022