Introduction

Mold Technology Adapting has become a vital factor in today’s manufacturing industries, as molds continue to shape products used across sectors such as consumer goods, automotive, medical, and industrial applications. As global markets evolve and customer expectations rise, mold manufacturers must continuously adapt their technologies to remain competitive. Growing demands for faster production cycles, complex and customized designs, and higher operational efficiency are driving significant changes in the mold-making process. In response, mold technology is adapting through the adoption of advanced manufacturing techniques, digital tools, and innovative design strategies. This article explores how Mold Technology Adapting to changing market dynamics and customer needs is reshaping the future of modern manufacturing.

Increased Focus on Customization and Flexibility

Adaptation:

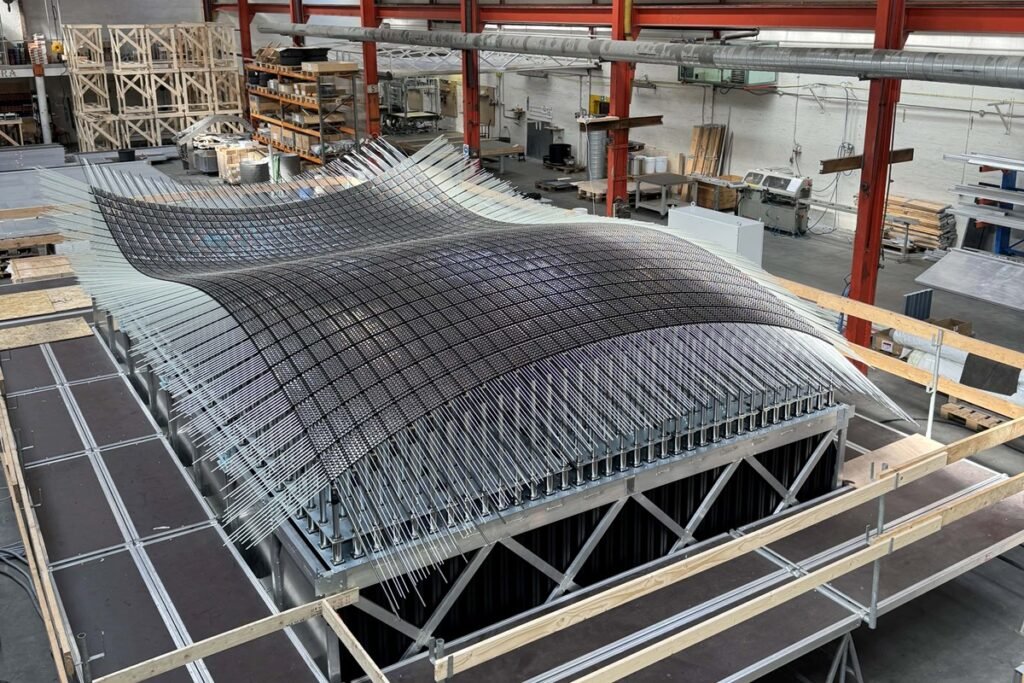

In today’s competitive market, customer expectations are higher than ever, with a growing demand for products that combine superior quality with precise customization. This shift has accelerated Mold Technology Adapting toward more flexible and customizable molding solutions. Mold manufacturers are now leveraging advanced design methodologies, digital simulation, and innovations such as 3D printing to develop molds that meet highly specific product requirements. As a result, Mold Technology Adapting enables faster design modifications, improved accuracy, and greater responsiveness to evolving customer needs, helping manufacturers deliver tailored solutions without compromising efficiency or performance.

Impact:

Customization is no longer a luxury—it has become a core requirement in modern manufacturing. This shift is a key driver behind Mold Technology Adapting to more agile and responsive production methods. Manufacturers are increasingly relying on digital modeling, rapid prototyping, and additive manufacturing to develop molds that can be efficiently modified for different sizes, shapes, and material specifications. Through Mold Technology Adapting, companies gain the flexibility to serve niche markets while maintaining scalability, enabling them to deliver highly personalized solutions for both low-volume custom products and high-volume mass-market production without sacrificing speed or quality.

Emphasis on Speed and Efficiency

Adaptation:

With shorter product life cycles and increasing pressure to accelerate time-to-market, Mold Technology Adapting has become essential for manufacturers seeking higher production speed and operational efficiency. Reducing cycle times is now a top priority, driving continuous advancements in mold design, tooling materials, and manufacturing processes. Through Mold Technology Adapting, companies are implementing smarter cooling systems, optimized cavity layouts, and advanced machining techniques to achieve faster output while maintaining precision and consistent product quality.

Impact:

To achieve shorter cycle times, Mold Technology Adapting is driving manufacturers to invest in advanced cooling solutions and automated production processes. Innovations such as conformal cooling channels enable precise temperature control within the mold, significantly reducing cooling time and increasing overall productivity. In parallel, Mold Technology Adapting includes the integration of automation technologies—such as robotic handling systems and AI-driven process control—to streamline production lines, enhance consistency, and minimize human error. These advancements allow manufacturers to maintain high output levels while ensuring repeatable quality and operational efficiency.

Integration of Sustainability in Mold Manufacturing

Adaptation:

As sustainability becomes a strategic priority for both manufacturers and end users, Mold Technology Adapting is playing a vital role in reducing environmental impact across production processes. This shift includes increased use of eco-friendly and recyclable materials, optimized mold designs that minimize material waste, and energy-efficient manufacturing techniques. Through Mold Technology Adapting, manufacturers are also lowering energy consumption during mold fabrication and operation, helping businesses meet sustainability goals while maintaining high performance and cost efficiency.

Impact:

The adoption of sustainable practices is accelerating as Mold Technology Adapting addresses both environmental and operational concerns. Manufacturers are increasingly selecting recycled or recyclable materials for their molds and implementing energy-efficient equipment to reduce their carbon footprint. Additionally, the use of biodegradable materials and the ability to recycle scrap significantly contribute to greener production processes. Through Mold Technology Adapting, digital tools are also employed to optimize material usage, minimize waste, and enhance overall efficiency—helping companies meet growing consumer demand for sustainable products without compromising on quality or productivity.

Incorporation of Digital Technologies and Automation

Adaptation:

The introduction of digital technologies and automation into mold manufacturing is revolutionizing the industry. By incorporating sensors, data analytics, and AI, manufacturers can enhance the accuracy of their molds and optimize the production process.

Impact:

Digital technologies such as Internet of Things (IoT) sensors and real-time monitoring systems enable manufacturers to track every stage of the mold-making process. This data-driven approach allows for predictive maintenance, minimizing downtime, and ensuring high-quality output. Additionally, AI-driven design and simulation tools enable quicker iterations of mold designs, optimizing performance and reducing the trial-and-error time in the prototyping phase.

Advances in Materials and Coatings

Adaptation:

As industries demand higher-performance products, mold manufacturers are adapting by using advanced materials and coatings. These innovations help molds last longer, perform better, and withstand harsh production conditions.

Impact:

New materials such as high-performance alloys, composites, and ceramic coatings are being used to create molds that can endure higher temperatures, pressures, and abrasive forces. These materials offer enhanced durability and wear resistance, increasing mold life and reducing maintenance costs. Coatings like titanium nitride (TiN) and chrome plating are becoming more common, as they provide superior protection against corrosion and wear, improving the overall performance of molds.

Globalization and Market Expansion

Adaptation:

With globalization, mold manufacturers are catering to a broader range of industries and regions. To meet the demand for international markets, mold manufacturers are investing in more flexible manufacturing systems that allow them to produce molds suitable for a variety of different industries.

Impact:

Mold manufacturers are increasingly offering solutions that cater to different market requirements. For instance, they might design molds to comply with international standards, incorporate local preferences, or accommodate regional regulations. This approach not only helps them penetrate global markets but also ensures that their products remain competitive on an international scale. Additionally, outsourcing and partnerships with overseas suppliers are becoming more common to meet the specific needs of different regions and industries.

Conclusion

As markets evolve, mold technology must continue to adapt. Innovations in customization, speed, sustainability, digital technologies, materials, and globalization are reshaping the mold manufacturing industry. By embracing these changes, manufacturers can meet the demands of modern markets and position themselves as leaders in an increasingly competitive global landscape.

Frequently Asked Questions (FAQs)

Q1: How is 3D printing changing mold manufacturing?

A: 3D printing allows for rapid prototyping and more complex, customized mold designs, reducing production time and costs. It enables manufacturers to quickly adjust molds and create products that meet unique specifications.

Q2: What are conformal cooling channels, and how do they improve mold efficiency?

A: Conformal cooling channels are designed to optimize the cooling process by following the shape of the mold. They help reduce cooling time and improve product quality by ensuring even heat distribution.

Q3: How are mold manufacturers addressing sustainability?

A: Manufacturers are adopting eco-friendly materials, reducing energy consumption, and using digital tools to minimize waste during the mold production process. Many companies are also recycling scrap material from the molding process.

Q4: What role do digital technologies play in mold manufacturing?

A: Digital technologies, including sensors, IoT, and AI, allow manufacturers to monitor mold performance, predict maintenance needs, and optimize production processes for better accuracy and efficiency.

Q5: How are advanced coatings improving mold durability?

A: Coatings such as titanium nitride (TiN) and chrome plating offer protection against corrosion, abrasion, and wear, significantly extending the life of molds and reducing maintenance needs.

Sources

Plastics Technology – “Advances in Mold Technology for Customization and Efficiency.”

Manufacturing.net – “The Role of Digital Technologies in Modern Mold Manufacturing.”

IndustryWeek – “How Sustainability Is Shaping the Future of Mold Manufacturing.”