Introduction

In the world of mold manufacturing, market demand is a critical driver of production processes, design changes, and supply chain strategies. Mold manufacturers face the challenge of meeting fluctuating demands while maintaining high-quality standards, competitive pricing, and efficient production schedules. Whether responding to seasonal trends, new industry regulations, or shifts in consumer preferences, mold manufacturers must adapt quickly to ensure their operations stay aligned with market needs.

In this article, we will explore how market demand influences various aspects of mold manufacturing, from the types of molds produced to the materials and technologies used. We will also discuss strategies that manufacturers employ to remain agile in an ever-changing market landscape.

1. The Role of Market Demand in Shaping Mold Design and Production

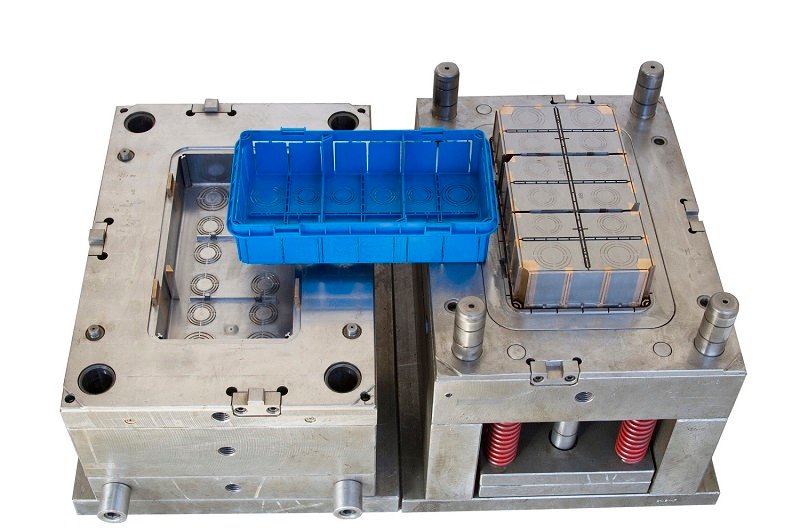

Market demand can have a direct impact on mold design, as manufacturers must respond to changes in product specifications, material requirements, and Mold Manufacturing technologies. For example, in industries such as automotive, electronics, and consumer goods, rapid shifts in market demand can lead to new product designs or materials that require updated molds.

Impact on Mold Design:

- Customization and Versatility: As consumer preferences evolve, mold manufacturers are increasingly required to design customized molds for a wider range of products. This means that mold designs must be flexible to accommodate changes in product shape, size, and features. Modular molds, which allow for interchangeable components, are becoming more popular as they enable manufacturers to quickly adjust mold designs to suit market needs without creating entirely new molds.

- Material Adjustments: When market demand shifts towards products requiring different materials, manufacturers must ensure that their molds are compatible with these new materials. For example, as the demand for eco-friendly or sustainable products grows, manufacturers may need to design molds that can handle biodegradable plastics or other alternative materials, which require different processing conditions.

- Rapid Prototyping and Shortened Lead Times: The demand for faster production cycles means that mold manufacturers are increasingly relying on rapid prototyping techniques. These methods allow manufacturers to test new mold designs quickly and refine them based on feedback. The faster turnaround time also aligns with industries like consumer electronics, where new products must be brought to market rapidly to capitalize on emerging trends.

2. The Influence of Market Demand on Production Schedules

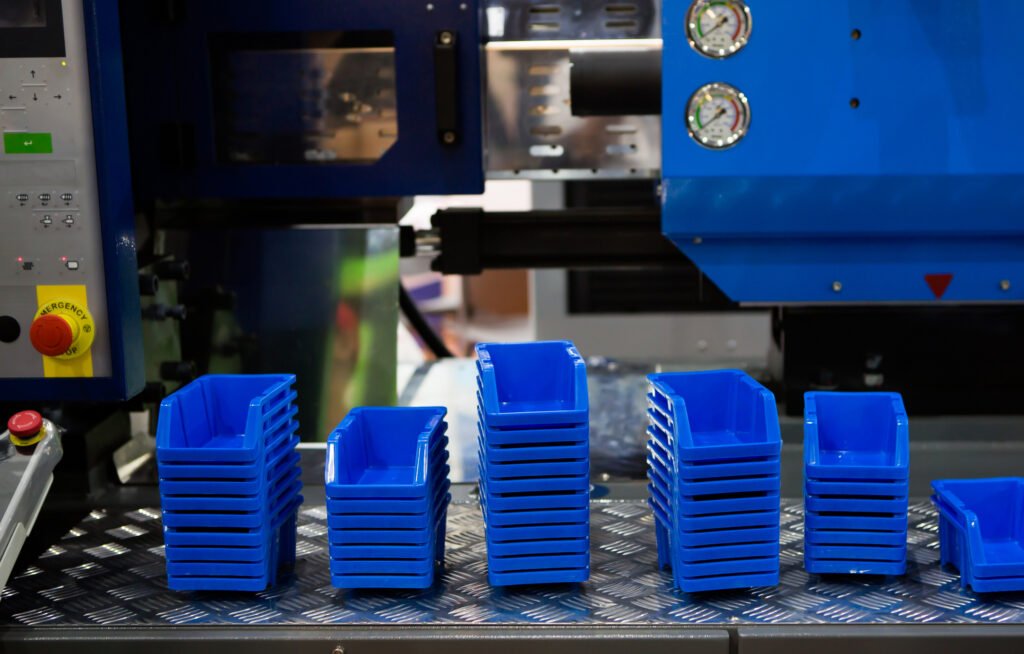

Fluctuating market demand can have a significant effect on production schedules. When demand is high, Mold Manufacturing must ramp up their operations to meet customer needs. Conversely, during slow periods, manufacturers may have to adjust production schedules to avoid overstocking inventory or incurring unnecessary operational costs.

Adapting to Fluctuating Demand:

- Just-in-Time (JIT) Manufacturing: To manage fluctuating demand, many mold manufacturers are implementing JIT manufacturing systems, which allow them to produce molds and components only as they are needed. This minimizes excess inventory and reduces lead times, ensuring that manufacturers can adjust production quickly in response to shifts in market demand.

- Flexible Workforce Management: To handle spikes in production demand, manufacturers often rely on a flexible workforce, hiring temporary workers or overtime shifts during peak periods. Conversely, during slow periods, they may reduce hours or implement furloughs to adjust labor costs without compromising production capabilities.

- Investment in Automation: Many manufacturers are turning to automation and robotics to improve production efficiency and respond to varying demand levels. Automated systems can handle repetitive tasks, allowing human workers to focus on more complex, high-value tasks. This also reduces the risk of human error and helps maintain consistent production even when schedules are tight.

3. Impact of Market Trends on Mold Materials and Technology

The growing trend towards sustainability, energy efficiency, and innovative product features has had a profound impact on the types of materials and technologies used in mold manufacturing. As market demand shifts, manufacturers must adopt new materials, tools, and production techniques to stay competitive.

Sustainability and Eco-Friendly Trends:

- Eco-Friendly Materials: As demand for sustainable products increases, mold manufacturers are adapting by using eco-friendly materials such as biodegradable plastics, recycled materials, and plant-based resins. The demand for these materials often requires the development of specialized molds that can process these materials without compromising performance or quality.

- Energy-Efficient Molds: There is a growing push for energy-efficient manufacturing processes, driven by both consumer demand and regulatory requirements. Manufacturers are incorporating energy-saving technologies into their molds, such as advanced cooling systems, to reduce energy consumption and improve efficiency.

- Advanced Mold Coatings and Surface Treatments: To meet the demands of industries that require high durability and performance, Mold Manufacturing are adopting advanced coatings and surface treatments that enhance mold lifespan, reduce wear and tear, and improve the quality of molded parts. These coatings can also help reduce friction and improve mold release, which is essential for high-volume production.

4. Cost Considerations in Response to Market Demand

When market demand increases, so does the pressure on manufacturers to control costs while meeting production goals. This can be particularly challenging in industries like automotive and electronics, where cost-cutting is essential to remain competitive, and the mold manufacturing process can be expensive.

Strategies for Cost Control:

- Material Cost Optimization: The cost of raw materials, such as high-grade steel or specialized alloys, can fluctuate significantly depending on market demand. Mold Manufacturing are increasingly seeking ways to optimize material usage by designing molds that minimize material waste and reduce production costs. Additionally, they may explore alternative materials that offer similar properties at a lower cost.

- Streamlining Production Processes: As demand increases, manufacturers often seek ways to streamline their production processes to reduce lead times and lower costs. This includes adopting lean manufacturing principles, which focus on eliminating waste and improving process efficiency.

- Outsourcing vs. In-House Production: In response to high market demand, some manufacturers may choose to outsource certain stages of mold production to specialized third-party vendors. This allows them to maintain flexibility and reduce capital investment in expensive mold-making equipment.

5. Adapting to Technological Advances Driven by Market Demand

As market demands evolve, there is an increasing emphasis on adopting cutting-edge technologies in mold design and production. New technologies such as 3D printing, simulation software, and AI-powered automation are reshaping the mold manufacturing industry.

Incorporating New Technologies:

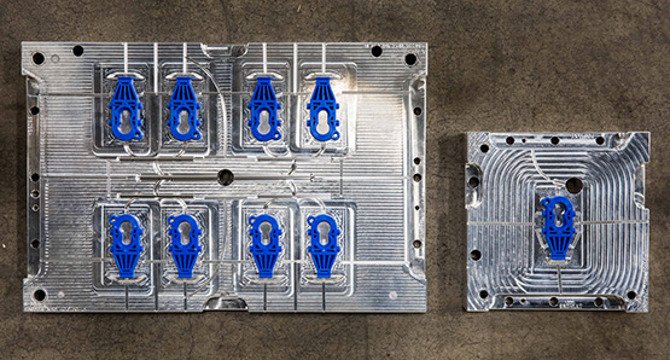

- 3D Printing for Mold Prototyping: 3D printing has revolutionized the way mold manufacturers prototype and test new designs. This technology allows Mold Manufacturing and manufacturers to quickly produce rapid prototypes and evaluate them for fit and function before investing in expensive molds. The demand for faster production cycles and customized products has accelerated the adoption of 3D printing technologies.

- Simulation Software for Mold Design: To meet market demand for more complex and higher-quality molds, Mold Manufacturing and manufacturers are leveraging simulation software to predict mold performance, optimize design, and reduce the risk of defects. These software tools can help manufacturers analyze the flow of materials, cooling times, and mold stress before physical production begins, ensuring higher precision and lower costs.

- AI and Robotics in Mold Production: The integration of artificial intelligence (AI) and robotics is helping Mold Manufacturing and manufacturers meet the growing demand for faster, more precise, and more cost-effective production. Robots are capable of performing repetitive tasks, such as mold finishing, while AI algorithms optimize production schedules, detect defects, and improve overall operational efficiency.

6. Dealing with Market Demand Variability

Some industries experience significant fluctuations in market demand, often due to seasonal factors, economic cycles, or sudden shifts in consumer preferences. Mold Manufacturing and manufacturers must be able to adapt quickly to these changes to avoid production delays or overstocking inventory.

Mitigating Demand Volatility:

- Demand Forecasting and Inventory Management: Mold Manufacturing are increasingly relying on advanced demand forecasting tools to predict fluctuations in market demand. These tools use historical data, trends, and predictive analytics to help manufacturers adjust production schedules and inventory levels in anticipation of demand spikes or downturns.

- Agile Manufacturing Systems: Agile manufacturing is designed to be highly flexible, allowing Mold Manufacturing and manufacturers to quickly switch between product lines, adjust production rates, and make design changes without significant delays. This is particularly valuable in industries with volatile market demand, such as consumer electronics or fashion.

Conclusion

Market demand plays a vital role in shaping every aspect of mold manufacturing, from design and material selection to production schedules and cost management. As demand fluctuates, mold manufacturers must remain adaptable, leveraging cutting-edge technologies and agile manufacturing systems to stay competitive. By staying attuned to industry trends and market shifts, mold manufacturers can effectively meet consumer needs while ensuring high-quality, cost-efficient production.

Frequently Asked Questions (FAQs)

Q1: How do market trends impact mold design?

A: Market trends, such as the demand for sustainability or new product features, drive mold manufacturers to adopt new materials and technologies. For example, eco-friendly products may require molds that are compatible with biodegradable plastics.

Q2: How do mold manufacturers handle fluctuating market demand?

A: Manufacturers adapt by using flexible production systems, such as JIT manufacturing, and leveraging advanced technologies like automation and forecasting software to adjust production schedules and reduce costs.

Q3: What role do technological advances play in meeting market demand?

A: Technological advances, such as 3D printing and AI-powered automation, enable mold manufacturers to respond to market demand more quickly and efficiently by improving design accuracy, production speed, and cost control.

Q4: How can manufacturers manage cost fluctuations driven by market demand?

A: By optimizing material usage, streamlining production processes, and strategically outsourcing certain production stages, mold manufacturers can control costs even when demand increases.

Q5: How do manufacturers forecast market demand for molds?

A: Manufacturers use advanced forecasting tools that analyze market trends, historical data, and external factors to predict demand and adjust production schedules accordingly.

Sources:

- Plastics Technology – “Understanding Market Trends in Mold Design.”

- Manufacturing.net – “The Role of Automation in Mold Production.”

- IndustryWeek – “Forecasting Demand in Mold Manufacturing.”