In the diverse world of manufacturing, choosing the right mold material is crucial for achieving the desired product quality and efficiency. Fiberglass molds have emerged as a popular choice across various industries due to their unique advantages. This article explores the benefits of using fiberglass molds in manufacturing and why they might be the ideal solution for your production needs.

Discover the benefits of using our molds in manufacturing, from cost-effectiveness to durability and design flexibility. Learn how fiberglass molds can enhance your production process and deliver superior results.

What Are Fiberglass Molds?

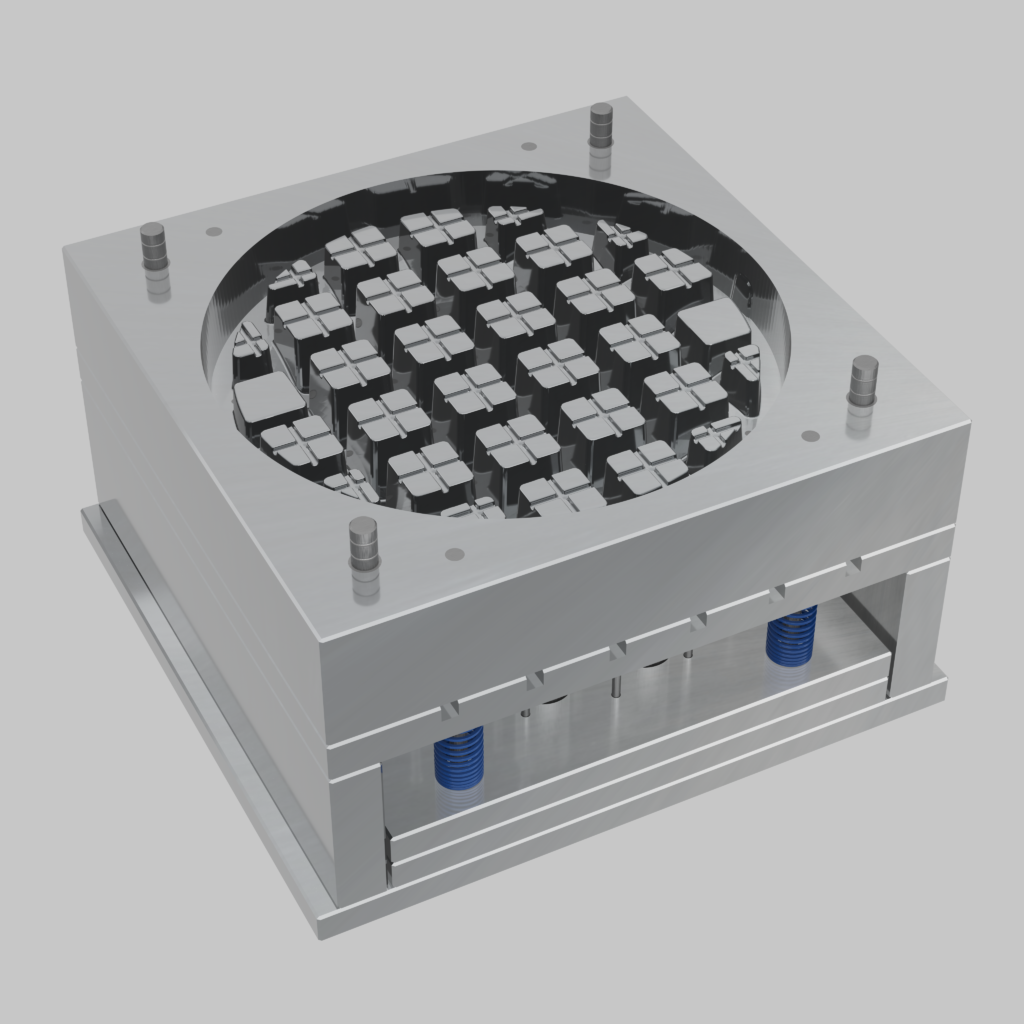

Fiberglass molds are created using fiberglass-reinforced plastic, a composite material made of fine glass fibers embedded in a resin matrix. This combination results in a lightweight yet strong and durable material that can be molded into complex shapes and used to produce a wide range of products.

Advantages of Fiberglass Molds

- Durability and Strength: molds are known for their high durability and strength. They can withstand repeated use without significant wear and tear, making them ideal for long production runs.

- Lightweight: Compared to metal molds, molds are significantly lighter. This makes them easier to handle, transport, and install, reducing labor costs and improving overall efficiency.

- Versatility: molds can be used to produce a variety of products across different industries, including automotive parts, boat hulls, architectural components, and more. Their ability to be shaped into intricate and detailed designs allows for great flexibility in product development.

- Cost-Effective: molds are generally less expensive to produce than metal molds, especially for low to medium volume production runs. Their long lifespan and low maintenance requirements also contribute to cost savings over time.

- Resistance to Corrosion: Unlike metal molds, fiberglass molds do not rust or corrode, making them suitable for use in harsh environments and with corrosive materials.

- Smooth Surface Finish: molds provide a smooth surface finish, reducing the need for additional finishing processes on the final product. This results in faster production times and lower costs.

Cost-Effectiveness:

One of the primary advantages of fiberglass molds is their cost-effectiveness. Compared to traditional metal molds, molds are significantly cheaper to produce and maintain. The lower cost of raw materials and the reduced need for specialized equipment make fiberglass molds an attractive option for manufacturers looking to optimize their budgets. Additionally, the lightweight nature of fiberglass reduces shipping and handling costs, further enhancing its economic benefits.

Durability and Longevity:

Fiberglass molds are known for their durability and longevity. They are resistant to corrosion, chemical damage, and environmental factors, which makes them ideal for use in harsh industrial settings. Unlike metal molds that may rust or degrade over time, fiberglass molds maintain their structural integrity, ensuring a longer lifespan and consistent performance. This durability translates into fewer replacements and repairs, saving both time and money in the long run.

Design Flexibility:

Another significant benefit of fiberglass molds is their design flexibility. The material can be easily shaped and molded into complex geometries that might be challenging or impossible to achieve with metal molds. This flexibility allows manufacturers to produce intricate designs with high precision, meeting specific client requirements and enhancing product innovation. Whether you need large, detailed components or small, intricate parts, fiberglass molds can deliver the precision and complexity you require.

Lightweight Nature:

The lightweight nature of fiberglass molds makes them easier to handle and maneuver during the manufacturing process. This ease of handling not only speeds up production times but also reduces the risk of workplace injuries related to heavy lifting and transportation. The reduced weight also means that less energy is required during the manufacturing process, contributing to a more sustainable and energy-efficient production line.

Applications of Fiberglass Molds

Fiberglass molds are used in a wide range of industries, including:

- Automotive: For producing lightweight and durable body parts, panels, and components.

- Marine: In the construction of boat hulls, decks, and other marine structures.

- Construction: For architectural elements, decorative panels, and custom building components.

- Consumer Goods: In the manufacturing of various plastic products, furniture, and sports equipment.

Conclusion

Fiberglass molds offer numerous benefits, including durability, lightweight, versatility, cost-effectiveness, resistance to corrosion, and a smooth surface finish. These advantages make them an excellent choice for a wide range of manufacturing applications. At Mold Technology, we specialize in creating high-quality fiberglass molds tailored to meet the specific needs of our clients. Contact us today to learn more about how our fiberglass mold solutions can enhance your production processes and deliver superior results.