Introduction

In the world of manufacturing, the Mold Quality Impact used in production processes significantly influences the performance and longevity of the final product. Whether producing automotive parts, medical devices, or consumer electronics, the mold’s design, material, and maintenance directly affect the product’s durability, precision, and consistency. Understanding the importance of mold quality is essential for manufacturers seeking to optimize their production processes and meet the high expectations of their customers.

The Relationship Between Mold Quality and Product Performance

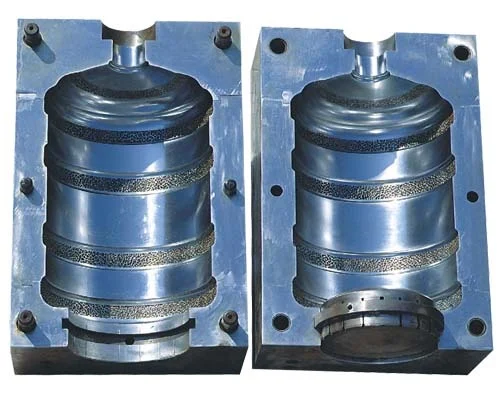

Molds are the foundation of manufacturing processes like injection molding, die casting, and compression molding. A well-designed and meticulously crafted mold ensures that the produced parts meet the required specifications, offering superior performance and reliability. Conversely, poor Mold Quality Impact can lead to defects, reduced durability, and inconsistent product performance.

Precision and Accuracy

Mold Quality Impact directly impacts the precision and accuracy of the final product. A high-quality mold is designed with tight tolerances, ensuring that the product’s dimensions and shape are consistent across all units. This is particularly important in industries like aerospace, automotive, and medical device manufacturing, where even slight deviations can result in malfunctions or safety risks.

Durability and Longevity

Durability is another critical factor influenced by mold quality. Molds made from high-grade materials like hardened steel or aluminum alloys ensure that the products produced are robust and have a longer lifespan. When molds are of inferior quality, they may wear out quickly, resulting in defects such as cracks, uneven surfaces, and weaker parts that fail to meet industry standards.

Surface Finish and Aesthetics

The surface finish of the final product is another aspect impacted by mold quality. A high-quality mold produces parts with smooth, flawless surfaces, which is especially important in consumer products that are visible to customers. In industries like electronics and automotive, where the aesthetic appearance of parts matters, the mold quality directly contributes to the final product’s visual appeal.

How Poor Mold Quality Affects Product Performance

On the other hand, poor mold quality can lead to various manufacturing issues, including:

- Inconsistent Dimensional Accuracy: Poor mold quality can result in variations in the size and shape of parts, making them unsuitable for further assembly or use.

- Increased Scrap Rates: Defective parts or molds that don’t perform as expected lead to higher rejection rates and wasted materials, driving up production costs.

- Extended Production Time: Molds that aren’t well-designed or constructed may require more time for maintenance and adjustments, slowing down the overall production process.

- Reduced Product Lifespan: Low-quality molds may produce parts with structural weaknesses, making them prone to early wear and tear, ultimately reducing the product’s longevity and reliability.

The Role of Mold Materials in Quality

The material used in mold manufacturing plays a crucial role in determining its quality and, by extension, the performance of the final product. Here are a few commonly used materials and their impact on mold quality:

- Steel: Steel molds are known for their strength and longevity, making them ideal for high-volume production runs where durability is essential.

- Aluminum: Aluminum molds are favored for their light weight and good thermal conductivity, making them suitable for rapid production of non-ferrous materials like plastics and soft metals.

- Copper-Alloy: Copper alloys are often used for high-precision molds, particularly in industries like electronics, where fine detail and accuracy are essential.

Choosing the right material for a mold depends on the desired properties of the final product, the volume of production, and the type of material being molded.

Maintaining Mold Quality for Consistent Performance

To ensure molds consistently perform at their best, proper maintenance is key. Regular cleaning, inspection for wear and tear, and timely repairs prevent defects and extend the mold’s lifespan. Implementing a structured maintenance schedule helps manufacturers avoid costly downtimes and ensures that production runs smoothly without quality issues.

The Role of Technology in Enhancing Mold Quality

Advancements in technology have played a vital role in improving mold quality. The introduction of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) allows manufacturers to create highly detailed and precise mold designs, ensuring the end product meets exact specifications. Additionally, 3D printing technology has introduced rapid prototyping, enabling manufacturers to test and refine mold designs before committing to full-scale production.

Key Industries Affected by Mold Quality

Many industries rely heavily on the quality of molds to produce high-performance products. Some of the key sectors where mold quality has a direct impact on product performance include:

- Automotive Industry: Molds are used to produce complex automotive components such as engine parts, bumpers, and interior components. High mold quality ensures parts are durable, lightweight, and precise.

- Electronics Industry: For electronics, precision molds are critical for producing parts like connectors, circuit boards, and housings. High mold quality ensures reliability and optimal performance of electronic devices.

- Medical Devices: In the medical field, molds are used to create parts for surgical tools, implants, and diagnostic equipment. Mold quality ensures safety, hygiene, and functionality in life-critical applications.

Conclusion

The impact of mold quality on the final product’s performance cannot be overstated. High-quality molds ensure precision, durability, and consistency, all of which are crucial for manufacturing products that meet customer expectations and industry standards. For manufacturers looking to improve their production processes, investing in high-quality molds and proper maintenance is an essential strategy to enhance overall product performance.

By recognizing the importance of mold quality, manufacturers can optimize their production capabilities, reduce waste, and ensure the long-term success of their products in the market. As technologies evolve, staying ahead in mold quality will be crucial to maintaining competitive advantage and achieving operational excellence.

FAQ (Frequently Asked Questions)

1. Why is mold quality so important in manufacturing?

Mold quality is crucial because it directly impacts the precision, durability, and overall performance of the final product. High-quality molds ensure consistent production of parts that meet design specifications, which are critical for industries like automotive, electronics, and medical devices.

2. How does poor mold quality affect production?

Poor mold quality can lead to issues like inconsistent product dimensions, higher scrap rates, longer production times, and decreased product longevity. These defects increase manufacturing costs and reduce overall efficiency.

3. What materials are best for creating high-quality molds?

Materials like hardened steel, aluminum alloys, and copper alloys are commonly used for high-quality molds. Each material offers different benefits, such as durability, precision, and cost-effectiveness, depending on the type of product being produced.

4. Can mold maintenance improve product quality?

Yes, regular mold maintenance, including cleaning, inspection, and repairs, ensures that molds perform consistently. Well-maintained molds lead to better product quality, reduced production delays, and a longer lifespan for the molds themselves.

5. How does 3D printing improve mold quality?

3D printing allows for rapid prototyping and precise design adjustments, enabling manufacturers to test mold designs before mass production. This technology helps refine mold quality, reduce errors, and shorten production lead times.

Sources:

- Manufacturing Today – The Importance of Mold Quality

- Advanced Mold Technologies – Understanding Mold Quality

- TechMold Solutions – Mold Design and Materials