Introduction

In the world of manufacturing, efficiency and cost-effectiveness are paramount. As industries demand quicker production times and lower operational costs, modular molds have emerged as a game-changer. These molds offer flexibility, cost-efficiency, and adaptability that traditional molds cannot match. By allowing manufacturers to easily swap out parts, modular molds streamline the production process, reduce costs, and increase production capabilities. In this article, we’ll explore how modular mold can save time and money while improving overall manufacturing efficiency.

What Are Modular Molds?

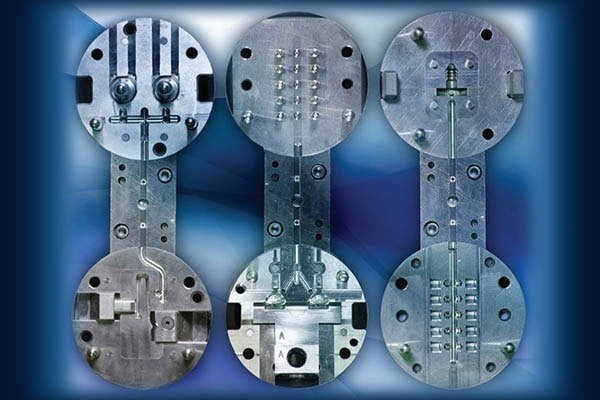

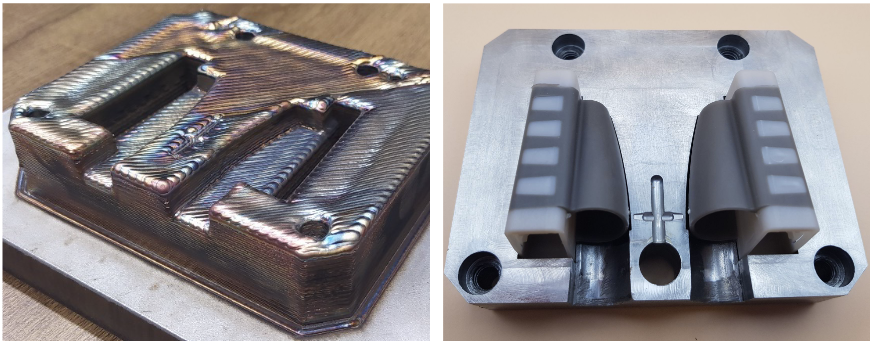

Modular mold are a type of mold that consists of interchangeable components or modules. Each module is designed to be easily replaced or combined with others, enabling manufacturers to adapt the mold for various part designs without creating an entirely new mold. This feature allows companies to save time and resources by reusing parts of the mold rather than building a new one from scratch.

These molds are especially beneficial for industries with varying production runs, including automotive, consumer goods, and electronics. Their adaptability makes them a versatile choice for manufacturers looking to increase production speed and reduce waste.

How Modular Molds Save Time and Costs

1. Reduced Tooling Costs

Traditional molds require the creation of an entirely new mold for each part or design change, resulting in significant tooling costs. In contrast, modular molds allow manufacturers to interchange components such as inserts, cores, and cavities, reducing the need for new molds for every part change.

How it helps:

- Less initial investment: With modular molds, manufacturers only need to invest in a basic mold setup and purchase additional modules as needed.

- Cost-effective for small production runs: Modular mold are ideal for low-volume production runs, as they eliminate the need for expensive new molds for each part.

2. Faster Production and Turnaround Times

Since modular molds allow for quick adjustments and part swaps, manufacturers can achieve faster turnaround times between production runs. This reduces the overall time it takes to switch between different designs, leading to quicker market launches and faster time-to-market for products.

How it helps:

- Shorter lead times: Manufacturers can quickly adapt the mold to different designs without waiting for a new mold to be fabricated.

- Quick changeover: Modular mold minimize downtime between different production runs, allowing the plant to remain operational and productive.

3. Increased Flexibility in Manufacturing

Modular molds offer greater flexibility in adapting to design changes, whether they are minor adjustments or major modifications. The ability to swap out individual components means manufacturers can quickly adapt their molds to changing customer demands or market trends without starting from scratch.

How it helps:

- Adaptability to design changes: Modular molds are perfect for products that frequently change in design or require various configurations.

- Customization: Customizing the mold to meet specific production needs becomes easier, offering manufacturers a competitive edge.

4. Reduced Maintenance and Repair Costs

Since modular molds consist of replaceable parts, it’s easier and more cost-effective to maintain and repair individual components rather than the entire mold. If a part becomes worn or damaged, it can be replaced without the need for an entire mold overhaul, reducing both maintenance and repair costs.

How it helps:

- Cost-effective repairs: Instead of replacing an entire mold, manufacturers can simply swap out the faulty module, saving time and money.

- Extended mold lifespan: Regular maintenance and replacing individual parts can extend the overall lifespan of the mold, reducing the frequency of mold replacements.

5. Lower Inventory Costs

With modular molds, manufacturers can reduce the number of molds they need to store, which directly impacts inventory costs. Instead of keeping a large number of molds for various designs, a single modular system can be adapted for many different parts by swapping out components as needed.

How it helps:

- Fewer molds to store: Manufacturers only need to keep the core mold and additional modules for different parts.

- Reduced storage and handling costs: The need for large storage areas for various molds is reduced, saving on warehouse costs.

Applications of Modular Molds

🚗 Automotive Industry

In the automotive sector, modular molds are used for the production of various components, such as bumpers, dashboard parts, and trim components. The ability to quickly change mold inserts and components makes modular molds ideal for manufacturing a wide range of parts with varying designs.

📱 Consumer Electronics

For consumer electronics, such as smartphone casings and battery compartments, modular molds allow manufacturers to adapt to design changes and production variations efficiently. The flexibility to quickly switch mold parts ensures that the manufacturing process remains agile and responsive to market trends.

🏠 Household Goods

In the production of household goods, such as kitchenware, plastic containers, and toys, modular molds can be customized to handle different shapes and sizes, making them a cost-effective solution for manufacturers with diverse product lines.

Advantages of Modular Molds

✅ 1. Cost Savings

The ability to reuse parts and avoid the need for new molds significantly reduces overall production costs. Manufacturers can achieve the same output with less investment in new tooling.

✅ 2. Improved Production Efficiency

Modular molds facilitate quick changeovers, leading to shorter lead times, faster production cycles, and ultimately more products in less time. This boosts overall manufacturing efficiency.

✅ 3. Increased Versatility

The flexibility to use one mold for multiple designs or configurations makes modular molds suitable for a variety of industries. Their adaptability makes them ideal for businesses that need to adjust quickly to customer demands.

✅ 4. Easier Maintenance and Repair

The modular nature of these molds allows individual components to be easily replaced or repaired, extending the mold’s lifespan and reducing maintenance costs.

Challenges of Modular Molds

❌ 1. Initial Setup Costs

While modular molds save money in the long run, the initial investment in a modular system can be higher than traditional molds due to the need for various modules. However, this cost is offset over time through savings in tooling, repairs, and maintenance.

❌ 2. Complexity in Design

Designing modular molds can be more complex than traditional molds, as they require careful consideration of the interchangeability of parts and the overall mold system. This can lead to longer design times initially.

Conclusion

Modular molds offer a wealth of benefits for manufacturers looking to optimize production efficiency and reduce costs. Their flexibility, cost-efficiency, and quick adaptability make them an excellent choice for industries that require frequent design changes and quick turnaround times. While there may be an initial investment in setting up a modular system, the long-term savings and efficiency gains make it a smart choice for many manufacturers. By improving tooling flexibility, reducing lead times, and simplifying maintenance, modular molds are an essential tool in modern manufacturing.

Frequently Asked Questions (FAQs)

Q1: What are the main benefits of using modular molds?

A: Modular molds offer cost savings, faster production times, increased flexibility, and easier maintenance, making them ideal for industries with frequent design changes or low-volume production.

Q2: Are modular molds suitable for all types of manufacturing?

A: Modular molds are versatile and can be used in various industries, including automotive, consumer goods, and electronics, making them suitable for manufacturers with diverse product lines.

Q3: How do modular molds reduce maintenance costs?

A: Since modular molds consist of replaceable parts, manufacturers can replace only the damaged or worn-out components, rather than the entire mold, which reduces maintenance costs.

Q4: Are there any disadvantages to modular molds?

A: The main disadvantages of modular molds are the initial setup cost and the complexity in design. However, these are typically offset by the long-term cost savings and increased production efficiency.

Sources

- Aluminum Die Casting for the Automotive Industry – Manufacturing Insights, 2021

- Aerospace Aluminum Casting Applications – Aerospace Industry Reports, 2020

- Die Casting Process Efficiency – Industrial Molding Magazine, 2022