Introduction

In today’s world, where precision and durability are paramount, plastic fitting molds have become an essential component in the plumbing industry. These molds are responsible for creating the fittings that connect various parts of plumbing systems, such as pipes, faucets, and valves. Ensuring that these components fit together perfectly is crucial to the integrity and efficiency of the plumbing system. With the growing demand for efficient and reliable plumbing solutions, plastic fitting molds are taking center stage. This article explores how plastic fitting molds are revolutionizing plumbing systems, enhancing performance, and contributing to the overall durability and cost-effectiveness of installations.

The Role of Plastic Fitting Molds in Plumbing Systems

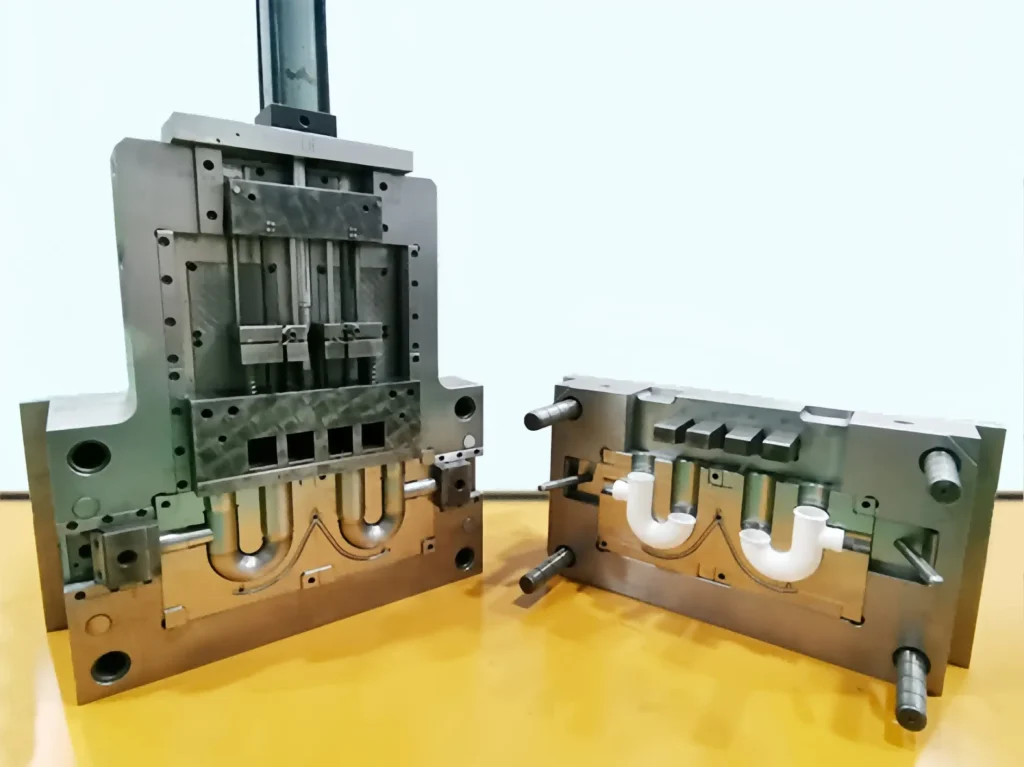

High-quality plastic components are essential in plumbing systems, including elbows, couplings, tees, and connectors that link different sections and ensure smooth fluid flow with a secure seal. Precision in manufacturing these fittings is critical, as even minor imperfections can lead to leaks, reduced efficiency, or system failure.

Key Functions of Plastic Fitting Molds:

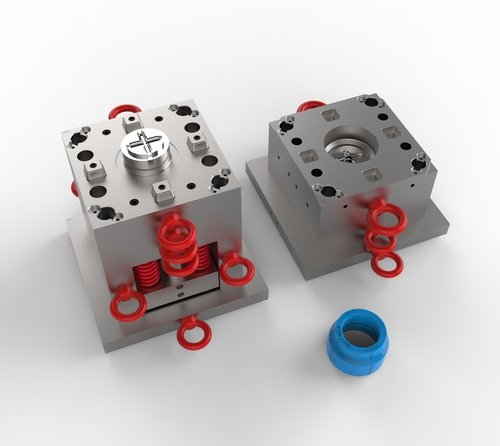

- Precision Manufacturing: These molds are engineered to produce fittings with precise tolerances, guaranteeing a seamless connection between pipes and other components. Such accuracy is essential to prevent leaks and ensure reliable, long-term system performance.

- Durability: These molds are made from materials such as aluminum or steel, ensuring they can withstand the pressures of high-volume production while maintaining their shape and functionality over time.

- Cost-Efficiency: The use of plastic fitting molds in manufacturing reduces material waste and lowers production costs. High-speed production techniques allow manufacturers to produce large quantities of fittings quickly and cost-effectively.

- Versatility: Plastic fitting molds can be customized for various types of fittings, allowing for adaptations to specific plumbing needs, whether for residential, commercial, or industrial systems.

How Plastic Fitting Molds Improve Plumbing System Efficiency

The primary benefit of using plastic fitting molds is the improvement in plumbing system efficiency. These molds contribute to better fluid flow, leak prevention, and overall system integrity. Here’s how:

- Leak Prevention: When fittings are molded with precise measurements, the risk of leaks is significantly reduced. Tight-fitting joints ensure that pipes stay sealed under high pressure and flow conditions.

- Increased Flow Capacity: Properly molded plastic fittings contribute to smoother transitions between pipes, reducing resistance and enhancing the overall flow of fluids. This is especially important in larger commercial plumbing systems where maintaining optimal flow is essential.

- Lightweight Construction: Plastic fittings are much lighter than traditional metal fittings, which simplifies the installation process. They can be easily transported and installed, reducing labor costs and improving overall system reliability.

The Benefits of Plastic Fitting Molds in the Plumbing Industry

The plumbing industry benefits in numerous ways from the use of plastic fitting molds, especially as demand for plastic-based solutions increases due to their cost-effectiveness and performance. Below are some of the major benefits:

1. Lower Manufacturing Costs

The cost of producing plastic fittings is significantly lower than traditional metal fittings due to the lower material costs and faster production speeds. In addition, the efficiency of plastic fitting molds reduces labor costs associated with manual assembly and welding, further lowering costs.

2. Customization for Specific Needs

Plastic fitting molds can be customized to produce fittings for specific applications. This versatility allows manufacturers to produce fittings in different shapes, sizes, and designs to meet the needs of different plumbing systems.

3. Corrosion Resistance

Plastic fittings are resistant to corrosion, unlike metal counterparts, which can deteriorate over time due to exposure to water and other harsh substances. This makes plastic fitting molds ideal for plumbing systems exposed to aggressive chemicals or harsh environments.

4. Sustainability

Plastic fitting molds contribute to sustainability efforts in the plumbing industry. Many modern plastic fitting molds are made from recyclable materials, which reduces waste and promotes eco-friendly manufacturing practices.

Applications of Plastic Fitting Molds in Plumbing Systems

Plastic fitting molds are used in various plumbing systems across different industries. Here are some common applications:

1. Residential Plumbing Systems

In residential plumbing, plastic fittings are used for everything from connecting pipes under sinks to setting up entire home water supply systems. Their cost-effectiveness, ease of installation, and reliability make them the preferred choice for many homeowners and contractors.

2. Commercial Plumbing Systems

Commercial buildings require large and complex plumbing networks, and plastic fitting molds allow for quick and precise manufacturing of fittings to meet the system’s needs. The lightweight nature of plastic fittings makes installation more manageable in these larger-scale applications.

3. Industrial Applications

Plastic fitting molds are used in industrial applications where fluids or gases need to be transported securely. Industries such as manufacturing, agriculture, and even the food and beverage sector rely on precision molded plastic fittings to ensure seamless, leak-proof systems.

The Technology Behind Plastic Fitting Molds

The advancement in mold-making technology has revolutionized how plastic fittings are produced. With the use of computer-aided design (CAD) software and automated machinery, manufacturers can now design and produce complex molds that meet tight tolerances. The evolution of injection molding, in particular, has allowed for greater speed and precision, resulting in higher-quality fittings at a reduced cost.

Key Technological Innovations:

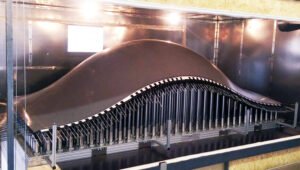

- 3D Printing for Prototype Fittings: 3D printing is increasingly being used to create prototype plastic fittings quickly, allowing manufacturers to test designs before mass production.

- High-Pressure Injection Molding: High-pressure injection molding enables the rapid production of large volumes of plastic fittings with consistent quality. This process has significantly improved production times and cost-efficiency.

- Precision CNC Machining: CNC machining provides an extra level of precision for mold-making, ensuring that every fitting produced is manufactured to the exact specifications required for optimal performance.

Conclusion

Plastic fitting molds are a game-changer in the plumbing industry, offering a combination of precision, cost-effectiveness, and durability. Their ability to create high-quality, tightly fitting components ensures efficient fluid flow and leak-free plumbing systems. As the demand for plastic fittings continues to grow, advancements in mold-making technology will further improve the performance and sustainability of these products.

By adopting plastic fitting molds, manufacturers can enhance the efficiency, cost-effectiveness, and reliability of plumbing systems, making them a crucial part of modern infrastructure.

Frequently Asked Questions (FAQs):

1. What materials are commonly used for plastic fitting molds?

The most common materials used for plastic fitting molds include thermoplastic polymers like PVC, ABS, and polypropylene, which offer durability, corrosion resistance, and cost-effectiveness.

2. How do plastic fitting molds contribute to leak prevention in plumbing systems?

Plastic fitting molds are designed to create perfectly fitted components with tight tolerances, ensuring a secure, leak-free seal between pipes and other fittings.

3. Can plastic fitting molds be customized for different plumbing needs?

Yes, plastic fitting molds can be customized to create a wide range of fittings for residential, commercial, and industrial plumbing systems, based on specific requirements like size, shape, and material compatibility.

4. Are plastic fittings as durable as metal fittings?

While metal fittings are typically stronger in high-pressure situations, plastic fittings offer excellent corrosion resistance and longevity, making them ideal for many plumbing applications.

5. How does the use of plastic fitting molds reduce production costs?

Plastic fitting molds reduce production costs by minimizing material waste, speeding up the manufacturing process, and lowering labor costs due to automated production methods.

Sources:

- “Molding Technology in Plumbing Systems.” Plumbing Manufacturing Journal, 2023.

- “Advancements in Plastic Injection Molding for Plumbing.” Plastics News, 2022.

- “The Role of Plastic Fittings in Modern Plumbing.” Journal of Building Materials, 2021.