Introduction

In the world of manufacturing, keeping molds in top condition is essential for maintaining high production efficiency and quality. predictive maintenance for molds has become a game-changer in mold management, offering manufacturers a proactive approach to mold care. By utilizing advanced technologies and data analytics, predictive maintenance helps detect potential issues before they result in costly downtime or mold failure. In this article, we explore how predictive maintenance can boost mold performance, extend their lifespan, and ensure consistent, high-quality production.

What Is Predictive Maintenance for Molds?

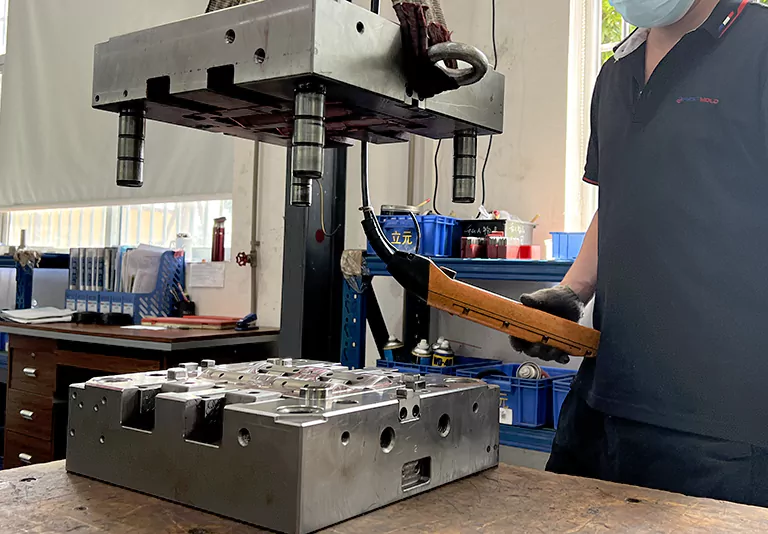

predictive maintenance for molds is a proactive strategy that uses data from sensors, machine learning algorithms, and other monitoring tools to predict when a mold is likely to experience a failure or performance issue. Unlike traditional maintenance methods that rely on scheduled servicing or reacting to problems after they occur, predictive maintenance enables manufacturers to address potential issues before they cause production delays or costly repairs.

By continually monitoring mold performance, temperature, pressure, and other variables, manufacturers can schedule maintenance only when it is necessary, which reduces unnecessary downtime and prolongs the life of the mold.

How Predictive Maintenance Improves Mold Performance

1. Early Detection of Potential Failures

One of the primary benefits of predictive maintenance for molds is its ability to detect problems early. By analyzing data from sensors embedded in molds, manufacturers can identify issues such as wear and tear, misalignment, or degradation of materials before they lead to mold failure. Early detection allows for timely repairs, preventing unexpected breakdowns that could halt production.

How it helps:

- Avoid costly breakdowns: predictive maintenance for molds helps spot issues before they escalate into expensive repairs or mold replacements.

- Minimize unplanned downtime: Identifying problems early means fewer interruptions to production, which leads to higher efficiency and output.

2. Increased Mold Lifespan

Molds are critical components in manufacturing processes, and ensuring their longevity is a priority for manufacturers. predictive maintenance for molds ensures that molds are kept in optimal condition, reducing the likelihood of premature failure. By addressing maintenance needs at the right time—rather than waiting for a mold to break—manufacturers can extend the lifespan of their molds, maximizing return on investment.

How it helps:

- Optimize mold use: Maintenance is performed based on the actual condition of the mold, extending its useful life.

- Reduce mold replacements: Proactively maintaining molds prevents premature replacements, saving on long-term costs.

3. Enhanced Production Efficiency

Molds that are well-maintained run more smoothly and produce parts with higher consistency and quality. Predictive maintenance ensures that molds operate at peak performance by preventing issues that could affect the production process, such as uneven heating, excessive wear, or pressure inconsistencies. This results in more consistent products and higher throughput.

How it helps:

- Ensure consistent product quality: Regular monitoring of molds ensures they are performing optimally, leading to consistent output with minimal defects.

- Boost production output: Molds that operate efficiently require fewer repairs and downtime, which increases the overall production rate.

4. Optimized Maintenance Scheduling

One of the most significant advantages of predictive maintenance for molds is the ability to schedule maintenance based on real-time data, rather than adhering to a rigid calendar. This data-driven approach allows manufacturers to perform maintenance only when needed, preventing unnecessary service while ensuring that the mold remains in excellent condition.

How it helps:

- Minimize downtime: Maintenance is performed only when required, minimizing disruption to production schedules.

- Cost-effective maintenance: Unnecessary maintenance activities are avoided, which leads to more efficient use of resources and labor.

5. Reduced Maintenance Costs

With predictive maintenance for molds, manufacturers can avoid over-maintaining their molds, which can be costly. Traditional maintenance schedules often involve performing routine checks even when they are unnecessary. Predictive maintenance, however, allows manufacturers to focus resources only on those molds that require attention, which reduces labor, material, and operational costs.

How it helps:

- Prevent costly repairs: By detecting issues early, predictive maintenance reduces the risk of severe breakdowns and expensive emergency repairs.

- Lower labor costs: Predictive maintenance allows for more efficient use of maintenance personnel, focusing their efforts where needed.

How predictive maintenance for molds Works in Mold Management

📊 Data Collection and Sensors

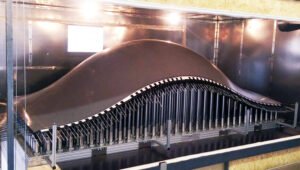

Predictive maintenance for molds involves using sensors to monitor various aspects of mold performance, such as temperature, pressure, vibrations, and wear levels. This real-time data is collected and analyzed to identify patterns and trends that could indicate potential problems.

🧠 Data Analysis and Machine Learning

Once the data is collected, machine learning algorithms analyze it to predict when a mold is likely to fail or require maintenance. These algorithms can spot subtle changes in performance that human inspectors might miss, offering more accurate predictions.

⚙️ Maintenance Action

When the system detects an issue or predicts a failure, maintenance personnel are alerted to take action. The system can also suggest the best course of action, such as replacing a part, recalibrating the mold, or performing a full inspection. This allows for proactive and targeted maintenance.

Applications of Predictive Maintenance in Molds

🚗 Automotive Industry

In the automotive sector, molds are used to create high-precision parts like bumpers, dashboards, and engine components. Predictive maintenance ensures that these molds remain in top condition, preventing defects in automotive parts that could lead to costly recalls or production delays.

🏠 Consumer Goods Manufacturing

For manufacturers of consumer goods like plastic containers or packaging, predictive maintenance helps keep molds performing at their best, ensuring consistent product quality and reducing downtime caused by mold failures.

🛠️ Tooling and Die Industry

In the tooling and die industry, where molds are subjected to constant wear and tear, predictive maintenance helps extend mold life, reduce downtime, and improve overall productivity by maintaining mold performance.

Benefits of Predictive Maintenance for Molds

✅ Increased Efficiency

Predictive maintenance allows manufacturers to monitor the performance of molds in real-time, optimizing operations and ensuring that molds are running smoothly.

✅ Cost Savings

By addressing issues early, predictive maintenance helps to reduce emergency repairs, replacement costs, and downtime, which saves manufacturers money.

✅ Improved Product Quality

Well-maintained molds lead to more consistent and higher-quality products, which can improve customer satisfaction and reduce waste from defective products.

✅ Enhanced Decision-Making

With predictive maintenance data, manufacturers can make more informed decisions about when and how to perform maintenance, avoiding unnecessary interventions and improving overall production planning.

Challenges of Predictive Maintenance for Molds

❌ Initial Setup Costs

The setup of predictive maintenance systems, including sensors and data analytics platforms, can involve significant initial investment. However, the long-term savings typically outweigh the upfront costs.

❌ Data Management Complexity

Collecting and analyzing vast amounts of data requires sophisticated software and trained personnel. Managing this data and ensuring its accuracy can be a challenge for some manufacturers.

Conclusion

Predictive maintenance has revolutionized mold management by offering a more proactive approach to mold care. By leveraging data and advanced analytics, manufacturers can detect potential issues early, extend the lifespan of molds, reduce downtime, and improve production efficiency. In today’s competitive manufacturing environment, predictive maintenance is no longer just an option; it’s a necessity for businesses looking to optimize mold performance, reduce costs, and ensure consistent product quality.

Frequently Asked Questions (FAQs)

Q1: What is the primary benefit of predictive maintenance for molds?

A: The primary benefit is early detection of potential issues, which allows manufacturers to address problems before they result in costly breakdowns or mold replacements.

Q2: How does predictive maintenance improve mold lifespan?

A: By performing maintenance only when necessary and addressing issues before they escalate, predictive maintenance extends the mold’s useful life and reduces the need for premature replacements.

Q3: What types of molds can benefit from predictive maintenance?

A: All types of molds, including those used in the automotive, consumer goods, and tooling industries, can benefit from predictive maintenance.

Q4: Is predictive maintenance costly to implement?

A: While there is an initial investment in setting up the system, the cost savings from reduced downtime and fewer repairs make predictive maintenance a cost-effective long-term solution.

Sources

- MoldMaking Technology – The Future of Predictive Maintenance in Mold Production

- Plastics Technology – How Predictive Maintenance Enhances Mold Performance

- Advanced Manufacturing – The Benefits of Predictive Maintenance for Molds

- Industry Today – Predictive Maintenance: Saving Costs and Increasing Efficiency in Mold Production