Introduction

In recent years, 3D printing in modern mold fabrication has shifted from being a prototyping novelty to a full-fledged tool in the manufacturing industry. With the increasing demand for speed, customization, and cost-efficiency, manufacturers are turning to 33D printing in modern mold fabrication — also known as additive manufacturing (AM) — to optimize mold-making workflows.

From complex geometries to faster turnaround times, 3D printing brings remarkable advantages to both prototype and production mold development. This article explores the transformative role of 3D printing in modern mold fabrication, covering technologies, benefits, real-world applications, and statistics that prove its growing influence.

What is 3D printing in modern mold fabrication?

3D printing in modern mold fabrication refers to the process of using additive manufacturing technologies to create molds or mold components. Rather than cutting or milling a mold from a block of metal or plastic, 3D printing in modern mold fabrication builds the mold layer by layer using digital CAD models.

There are two common ways 3D printing in modern mold fabrication:

- Printing the mold directly — Suitable for low-volume runs or prototype molds.

- Printing a mold insert or master pattern — Used for casting or hybrid tooling processes (e.g., combining 3D-printed inserts with metal bases).

Why Manufacturers Are Turning to 3D printing in modern mold fabrication

- Time Savings: Reduces mold creation time by 40–80%.

- Cost Efficiency: Lowers costs by up to 70% for prototype tooling.

- Design Flexibility: Allows for the creation of complex internal channels, conformal cooling, and lightweight structures.

- Iterative Testing: Enables fast design iterations and market validation.

- Sustainability: Generates less waste compared to subtractive methods.

Types of 3D Printing Technologies Used in Mold Making

| Technology | Description | Best For |

| SLA (Stereolithography) | Uses light to cure liquid resin layer by layer | High-resolution prototypes |

| FDM (Fused Deposition Modeling) | Melts and extrudes thermoplastic filament | Low-cost functional molds |

| SLS (Selective Laser Sintering) | Sintering powdered plastic layer by layer | Durable and heat-resistant mold inserts |

| DMLS (Direct Metal Laser Sintering) | 3D prints metal parts directly | Production-grade mold inserts |

| PolyJet | Jets and cures resin in ultra-fine layers | Smooth surface finish, complex designs |

Advantages of 3D Printing in Mold Fabrication

1. Faster Time-to-Market

Traditional mold fabrication can take 4–12 weeks. 3D printing in modern mold fabrication can reduce this to 2–7 days for prototypes and test molds.

Case Study: Whirlpool used 3D printing to develop injection mold inserts in 72 hours, compared to 8 weeks using conventional CNC machining.

2. Cost Reduction

Tooling for traditional mold making is expensive — especially for complex or low-volume production. 3D printed molds can cost $500 to $3,000, while traditional steel molds can run upwards of $10,000 to $50,000.

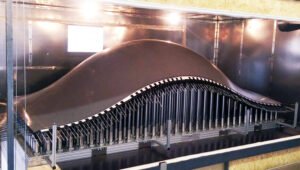

3. Complex Geometry and Conformal Cooling

3D printing allows engineers to create internal cooling channels that follow the contour of the mold cavity. This conformal cooling improves temperature regulation, reduces cycle time by up to 30%, and enhances part quality.

4. Material Efficiency

3D printing is an additive process, meaning there’s far less material waste. In CNC machining, as much as 60–70% of the original block may be removed.

5. Iterative Prototyping

Designers can test multiple mold concepts rapidly, optimizing performance before committing to full-scale tooling. This leads to better product design and fewer costly mistakes.

Common Applications of 3D Printed Molds

| Industry | Applications |

| Automotive | Rapid production of mold inserts for lights, air vents, and trims |

| Medical Devices | Prototyping enclosures, custom trays, and surgical components |

| Aerospace | Short-run parts with complex geometry and lightweight structures |

| Consumer Goods | Rapid testing of designs for appliances, toys, and electronics |

| Packaging | Prototype molds for bottle caps, closures, and containers |

Hybrid Mold Making: The Best of Both Worlds

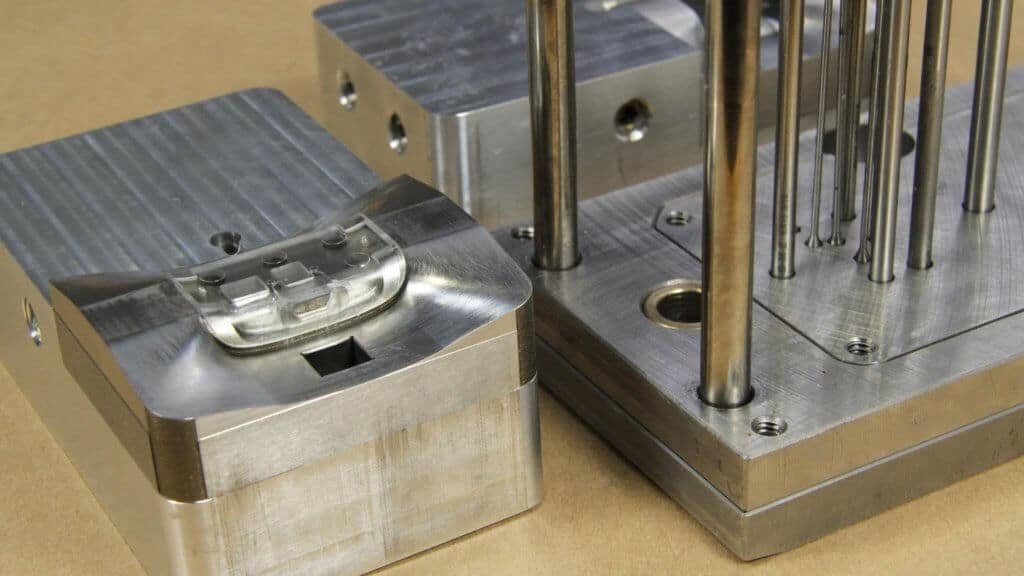

In many cases, manufacturers combine traditional machining with 3D printing to get the benefits of both. For example:

- Metal baseplate (machined) + 3D printed insert (PolyJet or SLA)

- This hybrid method offers:

- Cost savings

- Easy customization

- Precision in critical mold areas

Hybrid tooling is especially useful for bridge tooling, where a few hundred to a few thousand parts are needed before full-scale production begins.

Limitations of 3D Printing in Mold Fabrication

While 3D printing has many benefits, it’s not a complete replacement for traditional tooling (yet). Limitations include:

- Material durability: Most 3D printed materials cannot match the heat and pressure resistance of hardened steel.

- Surface finish: Printed molds often require post-processing to achieve desired smoothness.

- High-volume production: For runs exceeding 100,000 parts, traditional steel molds are still more cost-effective in the long term.

- Dimensional tolerances: Certain applications may demand tighter tolerances than some 3D printers can consistently provide.

Key Statistics and Market Trends

- The global 3D printing market in mold tooling is projected to grow from $3.8 billion in 2023 to $12.5 billion by 2030 (Source: Grand View Research).

- 63% of mold manufacturers in North America have adopted 3D printing in some form (SME 2023 survey).

- Conformal cooling channels can reduce injection molding cycle times by 15–40% (Source: Protolabs).

- Companies using 3D printed molds report a 20–50% reduction in total product development time.

Conclusion

The integration of 3D printing in modern mold fabrication is reshaping how manufacturers think about time, cost, and design. Whether it’s for prototyping, short-run production, or testing new products, additive manufacturing offers unmatched flexibility and speed.

As the technology continues to evolve, the use of 3D printed molds — either directly or as part of hybrid systems — is poised to become a cornerstone of modern manufacturing. For companies that prioritize innovation and agility, adopting 3D printing in modern mold fabrication is not just an advantage — it’s a necessity.

Frequently Asked Questions (FAQs)

Q1: Can 3D printed molds be used for injection molding?

A: Yes, especially for prototyping and short production runs. Materials like high-temp resins or metal powders (via DMLS) make this possible.

Q2: How long do 3D printed molds last?

A: It depends on the material. Resin molds may last for 50–500 shots, while metal printed inserts can handle thousands.

Q3: Is 3D printing more cost-effective than CNC machining for molds?

A: For low volumes and prototypes, yes. For high-volume, traditional CNC and steel molds remain more economical over time.

Q4: Can 3D printed molds produce complex shapes?

A: Absolutely. 3D printing excels at producing molds with internal channels, undercuts, and intricate geometries.

Q5: What industries are using 3D printed molds the most?

A: Automotive, aerospace, consumer electronics, medical devices, and packaging are leading adopters.

Sources:

- Grand View Research – 3D Printing Tooling Market Forecast

- Protolabs – Mold Design Whitepapers

- SME – Additive Manufacturing in Tooling

- MIT Technology Review – AM in Manufacturing

- Design News – 3D Printed Molds for Injection Molding