Introduction

Mold Manufacturing Challenges is essential for producing a wide variety of products in industries like automotive, electronics, and consumer goods. However, it is not without its challenges. Mold manufacturers must constantly address issues related to material selection, design complexity, mold wear, cycle time, and cost management. These obstacles can affect production efficiency, product quality, and profitability. In this article, we will explore the top 5 challenges faced in mold manufacturing and discuss practical solutions to overcome them.

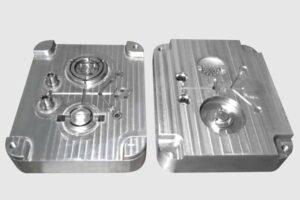

1. Material Selection and Compatibility

Challenge:

Selecting the right material for molds is a critical decision in the Mold Manufacturing Challenges process. Incorrect material choices can lead to poor Mold Manufacturing performance, premature failure, and costly defects in the final product. Additionally, compatibility between the mold material and the product material is essential to ensure the longevity of the mold and the quality of the molded products.

Solution:

To address this challenge, mold manufacturers must carefully evaluate materials based on their physical and mechanical properties. Common materials used in Mold Manufacturing Challenges include tool steels, aluminum, and various alloys. Conducting tests and simulations can help determine the best material for the job. Manufacturers should also ensure compatibility between the mold material and the materials used in the molding process, particularly when eco-friendly or specialty materials are required.

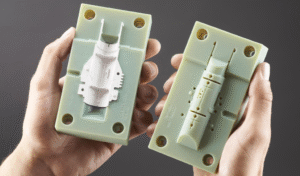

2. Mold Design Complexity

Challenge:

As products become more sophisticated, mold designs also become more complex. This complexity often leads to difficulties in manufacturing, such as the need for intricate geometries, undercuts, or precise tolerances. These challenges can increase the cost of production and make it harder to meet tight deadlines.

Solution:

Leveraging advanced CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) software can help mold manufacturers overcome design challenges by simulating and testing designs before physical production begins. These tools allow manufacturers to optimize the mold design for manufacturability, performance, and cost efficiency. Collaboration with experienced mold designers is also crucial to ensure that the complexity of the design doesn’t compromise the mold’s performance or manufacturability.

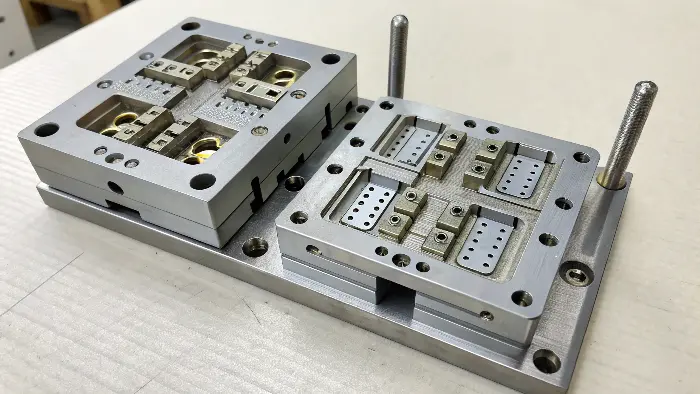

3. Mold Wear and Tear

Challenge:

Mold Manufacturing Challenges wear is inevitable, particularly when molds are used in high-volume production. Over time, wear and tear can lead to dimensional inaccuracies, surface defects, and reduced product quality. Factors like high temperatures, abrasive materials, and frequent molding cycles accelerate mold wear.

Solution:

Mold manufacturers can reduce wear by selecting high-performance materials that are resistant to abrasion and heat. Applying coatings such as nitriding or PVD (Physical Vapor Deposition) can also extend the life of molds by protecting them from wear and tear. Additionally, optimizing the molding process, such as controlling temperature and cycle time, can reduce the rate of mold wear. Regular inspections and proactive maintenance can also help identify potential issues early and prevent costly downtime.

4. Cycle Time and Productivity

Challenge:

Long cycle times can decrease productivity and increase Mold Manufacturing Challenges costs. The time it takes for the mold to cool, material to flow, and the entire cycle to complete is a critical factor in overall production efficiency. Reducing cycle time is essential to improve productivity and meet market demands in a timely manner.

Solution:

Improving cooling efficiency is one of the most effective ways to reduce cycle times. Manufacturers can use conformal cooling channels to optimize heat transfer and decrease cooling time. Automation and advanced molding machines can also help increase production speed while maintaining consistent quality. Implementing data-driven insights and predictive analytics can identify bottlenecks in the production process and suggest areas for improvement, allowing manufacturers to optimize cycle time and increase productivity.

5. Cost Management and Budget Overruns

Challenge:

Mold Manufacturing Challenges can be an expensive process, especially when molds are complex or require customization. Budget overruns can occur due to unexpected material costs, design revisions, and prolonged production cycles. Managing costs while maintaining high standards of quality is a constant challenge.

Solution:

To control costs, mold manufacturers can adopt lean manufacturing principles to eliminate waste and optimize production efficiency. Investing in high-quality, durable equipment may involve higher upfront costs, but it will save money in the long run by reducing maintenance and extending mold life. Additionally, manufacturers can consider outsourcing some aspects of mold production to specialized suppliers to reduce overhead costs. Regular reviews of production processes and cost-benefit analyses can help identify areas for improvement and cost reduction.

Conclusion

Mold manufacturing is full of challenges, but these can be effectively managed with the right strategies. By focusing on material selection, optimizing mold design, minimizing wear, improving cycle times, and controlling costs, manufacturers can overcome common obstacles and increase production efficiency. Staying updated with technological advancements and continuously refining processes will ensure that mold manufacturers remain competitive in an ever-evolving market.

Frequently Asked Questions (FAQs)

Q1: How do mold manufacturers select the right material for a mold?

A: Mold manufacturers evaluate materials based on their mechanical properties, compatibility with the molded product, and durability. Tools such as simulations and material testing help ensure the material is suitable for the specific molding process.

Q2: What is the role of CAD and CAE software in mold manufacturing?

A: CAD and CAE software help mold designers optimize mold designs, simulate performance, and test various factors such as cooling efficiency and material flow, which leads to better results and reduces costly design errors.

Q3: How can mold wear be minimized?

A: Mold wear can be minimized by selecting high-durability materials, applying wear-resistant coatings, optimizing temperature and cycle times, and conducting regular maintenance to address wear early.

Q4: How do manufacturers reduce cycle times?

A: Reducing cycle times can be achieved by optimizing mold cooling systems, using automated machinery, and analyzing production data to identify inefficiencies in the process.

Q5: What strategies can be used to manage costs in mold manufacturing?

A: Manufacturers can implement lean manufacturing principles, invest in high-quality equipment for long-term savings, and explore outsourcing certain production stages to control costs effectively.

Sources

Aluminum Die Casting for the Automotive Industry – Manufacturing Insights, 2021

Aerospace Aluminum Casting Applications – Aerospace Industry Reports, 2020

Die Casting Process Efficiency – Industrial Molding Magazine, 2022