Introduction

Mold manufacturing is a critical component of various industries, including automotive, electronics, and medical devices. The process involves creating molds that shape raw materials into finished products, and it requires precision, high-quality materials, and effective techniques. However, like any manufacturing process, mold production comes with its set of challenges. These challenges can affect efficiency, product quality, and costs. Understanding these obstacles and knowing how to address them is crucial for manufacturers aiming to maintain high production standards and stay competitive in the market.

1. Precision and Dimensional Accuracy

Challenge:

One of the most common challenges in mold manufacturing is achieving the required precision and dimensional accuracy. Even slight deviations in the mold design can lead to defects in the final product, which may result in increased rejection rates, higher costs, and production delays.

Solution:

To overcome this challenge, manufacturers must invest in advanced mold design technologies like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM). These tools allow for precise and accurate mold designs, reducing the chances of errors. Regular calibration of machines and tools also helps in maintaining high levels of precision. Additionally, using high-quality materials for molds ensures that the mold itself maintains dimensional accuracy over time.

2. Material Wear and Tear

Challenge:

Molds experience significant wear and tear due to repeated use, especially in high-volume production environments. Over time, mold surfaces can become rough or damaged, which can affect the quality of the final product, leading to defects such as poor surface finish, incorrect dimensions, or structural weakness in the molded parts.

Solution:

To prevent excessive wear and tear, manufacturers should select high-quality materials for mold production, such as hardened steel or tungsten carbide. These materials are more resistant to abrasion and ensure the longevity of the mold. Additionally, implementing regular mold maintenance schedules, including cleaning, polishing, and repairing damaged surfaces, helps maintain mold quality and extend its life.

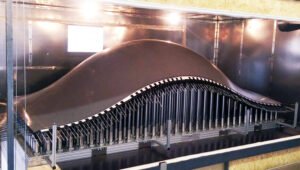

3. Mold Cooling Issues

Challenge:

Efficient cooling is a crucial part of the mold manufacturing process. Poor cooling can result in uneven molding, warping, or dimensional inaccuracies. Inadequate cooling systems can also lead to extended cycle times, reducing overall production efficiency.

Solution:

To overcome cooling challenges, manufacturers can use finite element analysis (FEA) software to optimize the design of cooling channels within the mold. This ensures that heat is distributed evenly, reducing the risk of deformation. Additionally, advanced cooling technologies such as water channels, conformal cooling, and gas-assisted cooling can be used to enhance the cooling efficiency and reduce cycle times.

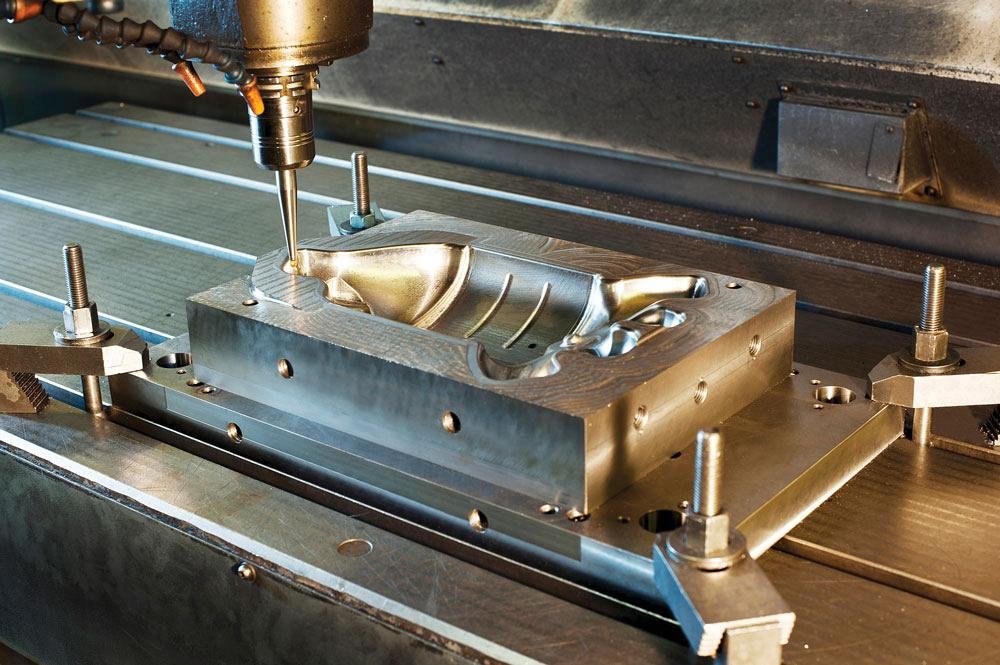

4. Mold Design Complexity

Challenge:

As product designs become more complex, molds need to accommodate intricate details and fine tolerances. This can lead to difficulties in mold design and manufacturing, particularly for parts with deep cavities, undercuts, or intricate geometries. Designing molds for these complex features requires high expertise and advanced tools.

Solution:

The solution lies in adopting modern design technologies like 3D printing for rapid prototyping and mold simulation software that can test designs before actual production. With these technologies, manufacturers can experiment with complex designs and optimize mold geometry before moving to the final production phase. Collaboration with experienced mold designers and engineers is also essential to ensure that the mold design is both feasible and cost-effective.

5. Cost Management and Budget Constraints

Challenge:

Mold manufacturing can be expensive due to the cost of high-quality materials, advanced machinery, and skilled labor. Balancing quality and cost is a significant challenge, especially for manufacturers working within tight budgets. Overestimating mold requirements or opting for lower-quality materials to reduce costs can lead to longer-term performance issues and higher production costs.

Solution:

To manage mold manufacturing costs effectively, manufacturers should focus on optimizing the mold design to reduce material waste and minimize the complexity of the mold. Additionally, adopting cost-efficient manufacturing technologies like additive manufacturing (3D printing) for prototyping and small-batch production can help reduce initial mold investment. Moreover, regular mold maintenance and repair can prevent costly replacements and ensure molds last longer.

Conclusion

Mold manufacturing is a complex process that requires precision, high-quality materials, and advanced technologies to overcome the common challenges it faces. Whether it’s achieving precision, minimizing wear and tear, improving cooling efficiency, tackling complex designs, or managing costs, manufacturers must adopt best practices, invest in modern technologies, and implement proper maintenance strategies to ensure the quality and efficiency of their molds.

By addressing these challenges effectively, manufacturers can improve their production processes, reduce costs, and produce high-quality products that meet customer expectations and industry standards.

FAQ (Frequently Asked Questions)

1. What are the common challenges in mold manufacturing?

Common challenges include achieving precision and dimensional accuracy, preventing wear and tear, addressing mold cooling issues, managing complex mold designs, and controlling costs.

2. How can precision and accuracy be ensured in mold manufacturing?

Using advanced design technologies like CAD and CAM, selecting high-quality mold materials, and regularly calibrating machines help ensure precision and accuracy.

3. How can mold wear and tear be minimized?

Using durable materials such as hardened steel and tungsten carbide, alongside regular maintenance and repairs, can reduce mold wear and tear.

4. What are some advanced cooling techniques for molds?

Conformal cooling, water channels, and gas-assisted cooling are advanced techniques that help improve cooling efficiency and reduce cycle times.

5. How can manufacturers manage mold manufacturing costs?

Optimizing mold design, adopting 3D printing for prototyping, and performing regular maintenance to extend mold lifespan can help manage costs effectively.

Sources:

- Moldmaking Technology – Overcoming Common Mold Manufacturing Challenges

- Advanced Manufacturing – Mold Design & Manufacturing Best Practices

- The Engineer – Challenges in Mold Manufacturing