Introduction

In the world of manufacturing and design, mold selection is critical to achieving the desired product quality and efficiency. Among the many types of molds, fiberglass molds stand out as an excellent choice for creating complex designs. Whether it’s for automotive parts, aerospace components, or decorative elements, fiberglass molds offer unmatched advantages in terms of strength, flexibility, and finish quality. In this article, we will explore what makes fiberglass molds the perfect solution for complex designs and why they have become the go-to option for industries that demand precision and high performance.

The Rise of Fiberglass Molds in Modern Manufacturing

Fiberglass molding has emerged as a preferred choice for industries requiring intricate, high-performance components. Unlike traditional molds made from metals or plastics, fiberglass molds combine the best qualities of both strength and flexibility. This combination allows manufacturers to create parts with highly detailed designs, all while maintaining the durability and strength necessary for demanding applications.

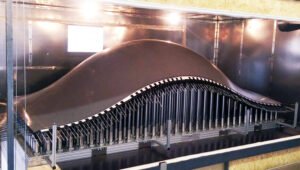

Fiberglass molds are made using a process that involves weaving glass fibers into a mesh, which is then coated with resin. This creates a lightweight yet highly durable mold capable of withstanding high temperatures and pressure, making it perfect for complex and high-precision parts. The flexibility of fiberglass also enables it to be used in a wide range of industries, from automotive and aerospace to consumer products and construction.

Why Fiberglass Molds Are Ideal for Complex Designs

Fiberglass molds offer several advantages over other types of molds, especially when it comes to producing complex designs. Let’s explore the key reasons why fiberglass molds are the perfect choice:

1. Strength and Durability

One of the primary reasons fiberglass molds are favored in complex designs is their strength. Fiberglass offers excellent structural integrity, ensuring that the mold can withstand repeated use without losing its shape or effectiveness. Whether the design requires intricate detailing or large-scale components, fiberglass molds provide the durability necessary to maintain high production standards over time.

- Fact: Fiberglass molds can typically endure temperatures up to 300°F (150°C) without warping or weakening, making them ideal for high-heat applications.

2. Flexibility and Design Freedom

Fiberglass molds are extremely flexible, which means they can be used to create highly intricate and custom designs. Unlike rigid metal molds, fiberglass molds can be tailored to fit complex shapes, curves, and angles. This flexibility is crucial for industries like automotive manufacturing, where custom parts with unique geometries are often required.

- Example: In automotive production, fiberglass molds are frequently used to create body panels, interior components, and other parts with complex shapes that would be difficult to achieve with metal molds.

3. High-Quality Surface Finishes

When producing components that require a smooth and aesthetically pleasing surface finish, fiberglass molds excel. The surface finish of a fiberglass mold is typically superior to that of other molds, especially when compared to metal or plastic molds. The smoothness and detail of the mold allow for high-quality, aesthetically appealing end products with minimal finishing required.

- Statistic: Fiberglass molds are known to reduce the need for secondary finishing steps by up to 40%, saving both time and labor costs.

4. Cost-Effective for Small to Medium Production Runs

While fiberglass molds may not be as cheap as some plastic molds, they offer a cost-effective solution for small to medium production runs. This makes them particularly useful for industries where the cost of creating multiple molds (such as metal molds) may not be justified by the volume of production.

- Fact: The average cost of a fiberglass mold is generally 20-30% lower than that of an equivalent metal mold, making it a more affordable option for short production cycles.

5. Lightweight Yet Robust

Fiberglass molds are lighter than metal molds, which makes them easier to handle and transport during the manufacturing process. Despite their light weight, they retain their robustness and strength, ensuring they can withstand the pressures of molding complex parts.

- Example: In aerospace manufacturing, fiberglass molds are used to create lightweight components that are still strong enough to meet the performance standards required for high-performance aircraft.

Applications of Fiberglass Molds in Various Industries

Fiberglass molds are widely used in a variety of industries due to their versatility and ability to produce high-quality, complex designs. Below are some of the primary industries that benefit from fiberglass molding:

Automotive Industry

The automotive industry relies on fiberglass molds to produce complex components such as body panels, engine parts, and interior trim. Fiberglass allows for intricate shapes and smooth surfaces, which are crucial for both the aesthetic appeal and functionality of automotive parts.

- Example: Custom car parts, like bumpers, hoods, and spoilers, often use fiberglass molds to achieve the necessary balance between strength and lightweight design.

Aerospace Industry

In the aerospace sector, fiberglass molds are used to manufacture components that need to meet strict weight and durability requirements. These molds are essential for creating lightweight but strong parts such as fuselage sections, wing components, and interior panels.

- Statistic: According to a 2020 report by the Global Aerospace Manufacturing Market, fiberglass composite materials are used in over 50% of modern aircraft production, offering both weight savings and strength.

Marine Industry

The marine industry also benefits from fiberglass molds, particularly for producing boat hulls, decks, and other components exposed to water. Fiberglass offers excellent resistance to corrosion, making it ideal for marine applications where durability is critical.

- Example: Fiberglass boats are favored for their low maintenance, high strength, and resistance to harsh marine environments, including saltwater.

Consumer Goods

Fiberglass molds are used in the production of various consumer goods, from furniture to sporting equipment. The high-quality finish and ability to create intricate designs make fiberglass an ideal material for items that require both durability and an attractive appearance.

- Example: High-end designer furniture, such as molded chairs and tables, often uses fiberglass molds to achieve the desired finish and structural integrity.

The Future of Fiberglass Molds

As industries continue to push the boundaries of design and performance, fiberglass molds are expected to play an even more critical role in manufacturing. The increasing demand for lightweight, durable, and complex components in sectors like automotive, aerospace, and consumer goods will drive innovation in fiberglass molding technology.

New advancements in materials science and mold-making techniques are likely to enhance the capabilities of fiberglass molds even further, enabling manufacturers to create more intricate designs, reduce production costs, and improve overall product quality.

Conclusion

Fiberglass molds have proven themselves to be the ideal choice for producing complex designs across a wide range of industries. Their strength, flexibility, high-quality finishes, and cost-effectiveness make them an indispensable tool in modern manufacturing. As industries continue to evolve, the demand for fiberglass molds will only increase, driving further innovation and ensuring that these molds remain at the forefront of advanced manufacturing techniques.

Frequently Asked Questions (FAQ)

1. What makes fiberglass molds ideal for complex designs?

Fiberglass molds offer a unique combination of strength, flexibility, and high-quality finishes, allowing them to accurately replicate intricate details and achieve complex geometries that would be difficult with other materials.

2. How are fiberglass molds different from metal molds?

While metal molds are typically stronger and more durable, fiberglass molds are lighter, more flexible, and often more cost-effective for small to medium production runs. They also offer smoother surface finishes and can be customized for more intricate designs.

3. Can fiberglass molds be used in high-temperature applications?

Yes, fiberglass molds can withstand temperatures up to 300°F (150°C), making them suitable for high-heat applications. However, for extremely high-temperature applications, such as metal casting, other materials may be required.

4. Are fiberglass molds cost-effective for small production runs?

Yes, fiberglass molds are often more cost-effective than metal molds for small to medium production runs due to lower initial setup costs and faster turnaround times.

5. What industries use fiberglass molds?

Fiberglass molds are used across various industries, including automotive, aerospace, marine, and consumer goods, due to their ability to produce lightweight, durable, and complex components.

Sources:

- Fiberglass Manufacturing & Applications – Industrial Manufacturing Journal, 2022

- Advances in Mold Making – Mold Engineering Reports, 2021

- Fiberglass Use in Aerospace – Global Aerospace Manufacturing Market, 2020